High Specific Gravity Tungsten Alloy

High Specific Gravity Tungsten Alloy

High specific gravity tungsten alloy is based on tungsten, with a small amount of Ni, Co, Mo, and other elements added to it. It is a typical two-phase alloy and is also called a "high-density alloy".

According to different product uses and working environment requirements, the tungsten content of high-specific gravity tungsten alloy products is usually 79%W~97%W, and the density range is 15.00g/cm³~18.50g/cm³. At the same time, some rare metal elements (Co, Mo, Cr, etc.) can be added to improve some properties of the product, such as hardness, ultimate tensile strength, yield strength elongation, etc.

High-specific gravity tungsten alloys are mainly divided into two categories, tungsten-nickel-copper alloy (W-Ni-Cu) and tungsten-nickel-iron alloy (W-Ni-Fe).

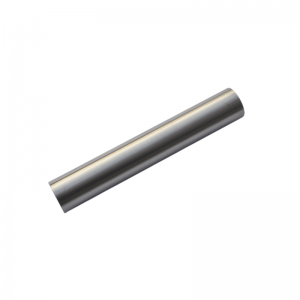

We provide high-specific gravity tungsten alloy products, including rods, plates, processed parts, etc. We have laser-cutting machines, CNC processing equipment, grinders, wire-cutting machines, and other processing equipment to provide you with a variety of precision processing services.

Application of High Specific Gravity Tungsten Alloy

• Aerospace gyroscope rotors, counterweights, shock absorbers.

• Armor-piercing cores for conventional weapons.

• Radiation shielding and components.

• Die-casting molds, flywheels and automatic watch pendulums for machinery manufacturing.

• Contacts and electrodes of electrical equipment, etc.

Physical Property

|

W(%) |

Density(g/cm3) |

Hardness(HRC) |

Tensile Strength(MPa) |

Elongatio(%) |

|

90 |

16.85-17.25 |

24-32 |

700-1200(600-800) |

20-33(4-8) |

|

92.5 |

17.15-17.85 |

25-30 |

700-1400(500-600) |

15-25(3-5) |

|

95 |

17.75-18.35 |

25-35 |

700-1200 |

8-15 |

|

97 |

18.25-18.85 |

30-35 |

600-1000 |

8-14 |

The sintering of high specific gravity tungsten alloy is a very important link. The sintering process has a great influence on the density, grain size, segregation, and microstructure of the alloy. We strictly control every production process to ensure the high quality of our products.

Do you want to know more about our products?

Contact Me

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: +86 156 1977 8518(WhatsApp/Wechat)

If you want more details and prices of our products, please contact our sales manager, she will reply as soon as possible (usually no more than 24h), thank you.