Vacuum coating, also known as thin film deposition, is a vacuum chamber process that applies a very thin and stable coating to the surface of a substrate to protect it from forces that could otherwise wear it out or reduce its efficiency. Vacuum coatings are thin, between 0.25 and ten microns (0.01 to 0.4 inches) thick.

Three forms of vacuum coating:

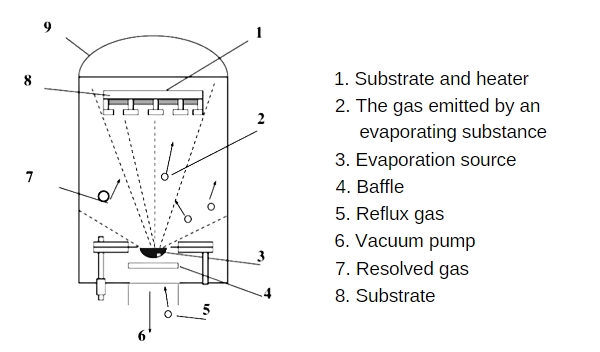

Evaporation coating

In vacuum, an evaporator is used to heat the evaporated material to sublimate it, and the evaporated granular flow is directed directly to the substrate and deposited on it to form a solid film, or a vacuum coating method is used to heat and evaporate the coated material. Our company is able to supply evaporators and heating elements, including various vessels made of refractory metals such as tungsten, molybdenum and tantalum, as well as tungsten wires and tungsten strands for heating.

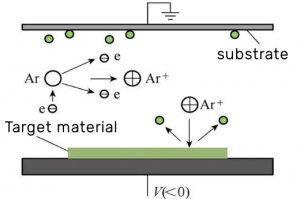

Sputtering coating

In a vacuum, the target surface is bombarded with high-energy particles, and the bombarded particles are deposited on the substrate. Usually, the material to be deposited is made into a plate-target material, etc., and refractory substances such as tungsten, molybdenum, tantalum, and titanium can be sputtered. Our company can provide high-purity tungsten plate, molybdenum plate, tantalum plate, titanium plate and various target materials, which can be used for sputtering coating.

Ion plating

Ion plating is to use gas discharge to ionize the gas or the evaporated material under vacuum conditions and deposit the evaporated material or its reactant on the substrate while the gas ions or the evaporated material ions are bombarded. In addition to non-ferrous metals, the coating materials of vacuum coating also include non-metals, namely oxides, silicon oxides and aluminum oxides.

Future trends

With the development of modern science and technology, vacuum coating technology is more and more widely used, not only plays an important role in consumer electronics, integrated circuits, optical optoelectronic components and other fields, but also in medical equipment, aerospace, solar energy, plastics, packaging, textile, machinery, anti-counterfeiting, construction and other fields.

BAOJI Winners Metal can provide crucible for evaporation such as tungsten, molybdenum, tantalum, etc., evaporation boat, sputtering target material (tungsten, molybdenum, tantalum, Niobium, titanium, etc.), electron gun tungsten wire, tungsten heater and other vacuum coating consumables, accessories。please contact us for more information(Whatsapp+86 156 1977 8518).

Post time: Aug-02-2022