Stranded tungsten wire is an ideal tungsten coil heater for thermal evaporation coating. It has become a key component in the vacuum coating industry and is widely used for its long-term reliability and efficiency. Tungsten wire provides better heat transfer and longer service life than other materials, making it the perfect choice for thermal evaporation coating. With its low cost and high performance, it's no wonder that stranded tungsten wire is becoming increasingly popular as a tungsten coil heater.

Tungsten Coil Heater Specifications

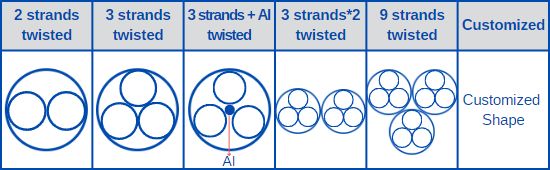

Specifications: φ0.76X3, φ0.81X3, φ0.85X3, φ1.0X3, φ1.0X2, φ0.81X4, φ0.81X3+AI

We provide customers with various solutions for tungsten wire stranding.

Stranded Tungsten Wire / Tungsten Coil Processing Flow

Step 1: Fill the tube made of iron or steel with powdered tungsten, and press the powder into shape by static pressure.

Step 2: Make it into a whole rod shape to ensure uniform force, the powder is squeezed, the volume becomes smaller, and it is easy to take out.

Step 3: Take it out and put it into the sintering furnace for sintering. The time varies according to the size of the rod, and the temperature is above 1000 degrees. Then it is swaged by swaging machine to improve performance.

Step 4: enter the wire drawing die for the wire drawing process. For example, 1.5kg tungsten rods can pull out a tungsten wire with a diameter of 1.588mm for about 40m, so that the tungsten wire is formed.

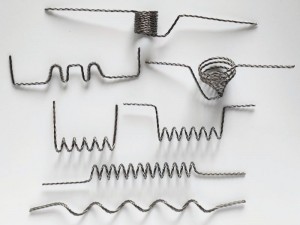

Step 5: Select the fine tungsten wire with the corresponding diameter according to the specifications, and then use professional equipment to twist, bend and other operations to produce the finished twisting tungsten wire or tungsten coil heater.

What is the use of stranded tungsten wire?

Stranded tungsten wire is mainly used as a raw material for heaters, and can also be directly used as a heating element for semiconductor or vacuum devices. Stranded tungsten wire is widely used in vacuum coating of thin film technology, metal evaporation, mirror industry, picture tube industry and lighting industry and other fields.

Advantages

Due to the characteristics of tungsten elements, stranded tungsten wire has the advantages of high hardness, high melting point, no air erosion at room temperature, and relatively stable chemical properties.

Want to know more about our products?

Post time: Apr-14-2023