Product characteristics, application markets and future trends of vacuum coated tungsten twisted wire

Vacuum coated tungsten twisted wire is a material with important application value and is widely used in the fields of optics, electronics, decoration and industry. This article aims to conduct an in-depth study of the product characteristics, application markets and future trends of vacuum coated tungsten stranded wire, and to illustrate it through data.

In the past few decades, vacuum coating technology has continued to develop, from the initial single film layer to the current multi-film layer, from traditional thermal evaporation to modern electron beam evaporation and ion beam deposition, vacuum coating technology has become a modern industry an integral part of. As one of the key consumables in vacuum coating technology, the use of tungsten twisted wire has been widely recognized and used.

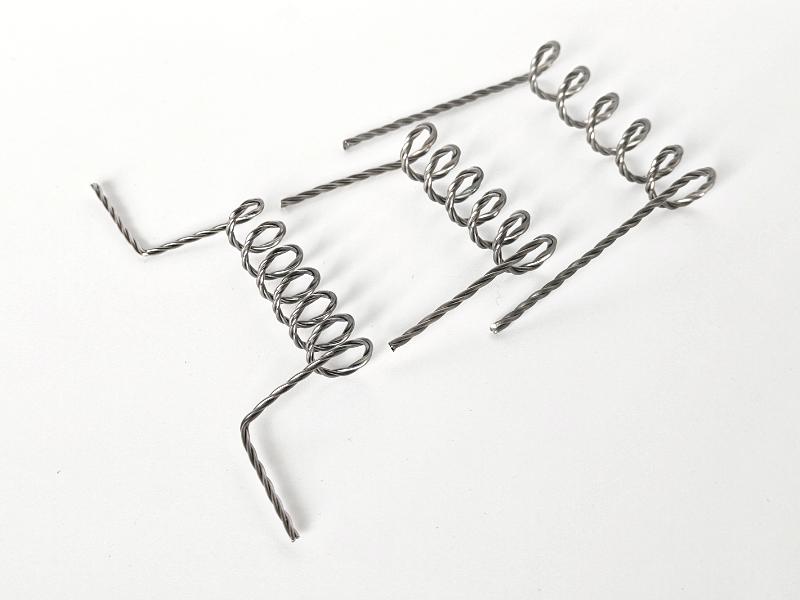

Tungsten twisted wire has high melting point, high density, high strength and good electrical conductivity. These characteristics make it play an important role in the vacuum coating process. First of all, tungsten twisted wire can be used as an evaporation source material to achieve high-efficiency and high-precision coating through electron beam evaporation or laser pulse heating. Secondly, tungsten twisted wire can also be used as a heater material to achieve rapid heat treatment of the film layer in a vacuum environment, thereby improving the adhesion and stability of the film layer. In addition, tungsten twisted wire can also be used as a supporting structural material to manufacture high-precision and highly stable coating equipment.

At present, the application market of vacuum coated tungsten twisted wire is constantly expanding. In the field of optics, tungsten twisted wire is widely used to manufacture high-quality optical lenses and prisms; in the electronic field, tungsten twisted wire is used to manufacture high-precision electronic devices and circuits; in the decorative field, tungsten twisted wire can be used to manufacture High-brightness decorative coatings; in the industrial field, tungsten twisted wire is used to manufacture high-hardness wear-resistant coatings and high-temperature components.

In the future, with the continuous development of science and technology, the application prospects of vacuum coated tungsten twisted wire will be broader. First of all, with the continuous emergence of new materials, the manufacturing technology of tungsten twisted wire will be further improved, making its performance more excellent and manufacturing more convenient. Secondly, with the improvement of people’s living standards, the demand for vacuum coated tungsten twisted wires in the fields of optics, electronics, decoration and other fields will continue to increase. In addition, with the development of Industry 4.0, the application of vacuum coated tungsten twisted wire in intelligent manufacturing, new energy, biomedicine and other fields will also be further expanded.

In short, as an important industrial material, vacuum coated tungsten twisted wire has excellent product characteristics, a wide range of application markets, and broad future development prospects. However, we should also see that with the rapid development of science and technology, we need to further explore and study the potential application value and market prospects of vacuum coated tungsten twisted wires in order to better meet the needs of social development.

Post time: Sep-11-2023