Tungsten stranded wire is a kind of consumable material for vacuum coating, which is generally composed of single or multiple doped tungsten wires in various shapes of metal products. Through a special heat treatment process, it has strong corrosion resistance and high temperature performance, good stability and long service life. It is currently widely used in vacuum coating of thin film technology, metal evaporation, mirror industry, aluminum and other decorative items, chrome plating, etc. Mirrors, plastic products, heating elements, picture tube industry and lighting industry and other fields.

Production process of tungsten stranded wire

1. Drawing: use a wire drawing machine and repeatedly draw the tungsten round rod to the appropriate size, such as Φ1.0mm, Φ0.8mm, Φ0.76mm, Φ0.6mm

2. Alkaline cleaning or electropolishing: the tungsten wire after alkali washing is whitish, and the tungsten wire after electropolishing has metallic luster

3. Joint stock: Twist the tungsten wire into 2 strands, 3 strands, 4 strands or more with a plying machine, and the tungsten strands are ready for use.

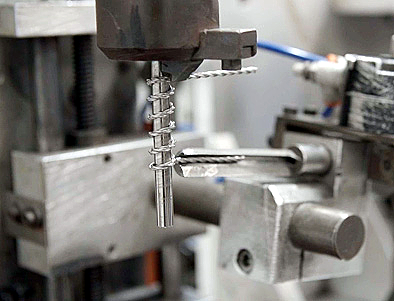

4. Molding: Use tungsten strand forming machine to process tungsten wire into various shapes of tungsten strand.

5. Inspection and warehousing: Use professional tools to check the appearance and measure dimensions, etc., and register suitable products for storage.

The working principle of tungsten stranded wire

Tungsten has high melting point, high resistivity, low vapor pressure and high strength, and is suitable for evaporators.The target material is placed in the tungsten stranded wire in the vacuum chamber. Under high vacuum conditions, the tungsten stranded wire is heated to evaporate it. When the mean free path of the evaporated molecules is greater than the linear size of the vacuum chamber, the atoms and molecules of the vapor are removed from the evaporation source. After the surface escapes, it is rarely impacted and hindered by other molecules or atoms, and can directly reach the surface of the substrate to be plated. Due to the low temperature of the substrate, it condenses to form a thin film.

About us

Baoji Winners Metal is a professional manufacturer of tungsten, molybdenum, tantalum and niobium material products. The company's main products are: tungsten, molybdenum, tantalum, and niobium crucibles, tungsten strands for coating, tungsten and molybdenum screws/bolts, ion implanted tungsten and molybdenum workpieces, and other tungsten, molybdenum, tantalum and niobium processed products. The products are mainly used in high temperature furnace, semiconductor ion implantation, photovoltaic single crystal furnace, PVD coating and other industries. If necessary, please contact us: +86 156 1977 8518 (Whatsapp)

Post time: Sep-21-2022