TZM alloy is currently the most excellent molybdenum alloy high temperature material. It is a solid solution hardened and particle-reinforced molybdenum-based alloy, TZM is harder than pure molybdenum metal, and has a higher recrystallization temperature and better creep resistance, the recrystallization temperature is about 1400 ° C, much higher For molybdenum, it can provide better solderability.

MHC is a particle-enhanced molybdenum alloy containing hafnium and carbon. Due to the relatively uniform distribution of ultrafine carbides, the material still exhibits the advantages of excellent heat resistance and creep resistance at a temperature of 1550 °C, and the recommended maximum operating temperature is also 150 °C higher than that of TZM. For example in extrusion dies, it can withstand extreme thermal and mechanical loads, so MHC materials are recommended for metal forming applications.

Molybdenum-zirconium alloy, doped with a small amount of zirconia (ZrO2) in pure molybdenum, can enhance the corrosion resistance and creep resistance of molybdenum.

Adding rare earth elements can not only improve the recrystallization temperature and high temperature creep resistance of molybdenum, but also significantly reduce the plastic-brittle transition temperature of molybdenum, increase the ductility, and improve the room temperature brittleness and high temperature sag resistance of molybdenum.

Application

Due to its excellent high temperature strength, high recrystallization temperature and good thermal conductivity, TZM alloy is widely used in aerospace, aviation and other fields, such as nozzle material, nozzle material, gas valve body, gas pipe pipeline. It can also be used as X-ray rotating anode parts, die-casting molds and extrusion molds, heating elements and heat shields in high-temperature furnaces.

MHC alloys are widely used in metal forming applications:

● Rare earth molybdenum wire is mainly used as electric light source filament, EDM electrode and high temperature furnace heating element.

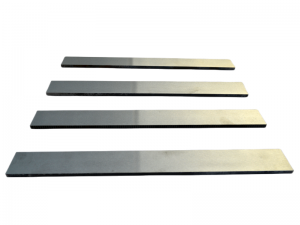

● Rare earth molybdenum plates and sheets are used as wafers for stamping into thyristors, as well as heat shields and guide sheets for electronic tubes.

● Rare earth molybdenum alloy can be used as high-quality steel hot perforation head, as well as aerospace and nuclear industry materials, X-ray pole targets, die-casting dies and extrusion dies.

● Rare earth molybdenum shaped products are used as glass melting electrodes, rare earth smelting electrodes, crucibles, high temperature sintering boats, high temperature radiation heat shields, flow ports, guide rails, pads, etc.

● Rare earth molybdenum alloys can also be used as hot cathode materials for medium and high power electronic tubes. The rare-earth molybdenum alloy thermal cathode material replaces the current spallation tungsten cathode, which has high operating temperature, radioactive contamination, and high brittleness, and can greatly reduce the operating temperature of the tube and improve reliability.

Baoji Winners manufactures primarily tungsten and molybdenum and its alloy materials and can be customized to meet customer needs. For more product information, please contact us (Whatsapp: +86 156 1977 8518).

Post time: Aug-02-2022