Tungsten, molybdenum, tantalum, and stainless steel products are widely used in various types of vacuum systems because of their excellent performance and performance characteristics. These materials play diverse and critical roles in various components and systems within vacuum furnaces, helping to increase their efficiency, reliability, and service life. The following are the applications of each material in the vacuum furnace industry:

Tungsten Products

1. Heating elements: Due to its high melting point and excellent thermal conductivity, tungsten is commonly used to make heating elements. Tungsten filament or rod heating elements provide uniform heating within the vacuum chamber, allowing for precise temperature control during heat treatment.

2. Heat shields and insulation layers: Tungsten heat shields and insulation components help minimize heat loss and maintain a stable operating temperature within the vacuum furnace. These components ensure thermal uniformity and protect sensitive materials from overheating.

3. Support Structure: Tungsten support structures provide structural stability and durability to various furnace components, ensuring they are properly aligned and functional under high-temperature conditions.

Molybdenum Products

1. Crucibles and boats: Molybdenum is widely used in the manufacture of crucibles and boats in vacuum furnaces to contain and handle materials in high-temperature processes such as melting, casting, and vapor deposition.

2. Heating elements and filaments: Molybdenum heating elements and filaments have excellent high-temperature resistance and oxidation resistance, making them suitable for vacuum furnace heating systems.

3. Molybdenum insulation components, such as sheets and foils, help reduce thermal conductivity and minimize heat transfer within the vacuum furnace chamber, thereby improving energy efficiency and temperature control.

4. Molybdenum fasteners: Due to molybdenum’s excellent high-temperature resistance and low vapor pressure, it is very suitable for connecting and reinforcing various components in vacuum chambers.

Tantalum Products

1. Heating elements and filaments: Tantalum heating elements and filaments have excellent corrosion resistance and high-temperature stability, making them ideal for use in vacuum furnace heating systems, especially in chemically aggressive environments.

2. Lining and shielding: Tantalum lining and shielding protect the inner surface of the vacuum furnace cavity from chemical erosion and contamination, ensuring the purity of the processed materials and extending the service life of the furnace components.

3. Tantalum fasteners: Tantalum has excellent high-temperature resistance and corrosion resistance, and is very suitable for connecting and reinforcing various components in vacuum chambers.

Stainless Steel Products

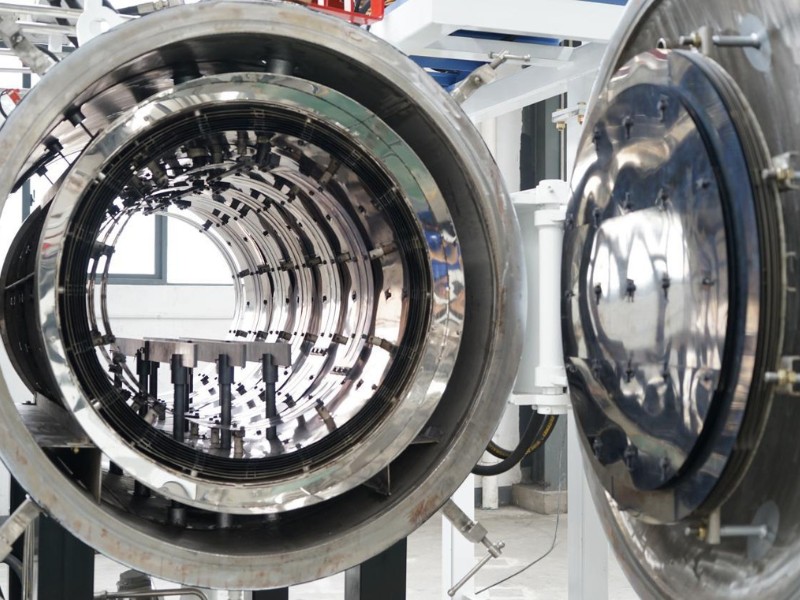

1. Vacuum chamber components: Due to its excellent mechanical strength, corrosion resistance, and weldability, stainless steel is often used to manufacture vacuum chamber components such as walls, flanges, and accessories. These components provide structural integrity and hermetic sealing, maintaining a vacuum environment and preventing gas leaks.

2. Vacuum pump components: Due to its durability and compatibility with vacuum conditions, stainless steel is also used in the construction of vacuum pump components, including casings, impellers, and blades.

Tungsten, molybdenum, tantalum, and stainless steel products are integral to the operation and performance of vacuum furnaces, enabling precise temperature control, thermal insulation, material sealing, and structural integrity in vacuum environments. Their unique properties make them an integral part of a wide range of heat treatment applications in industries such as aerospace, automotive, electronics, and materials science.

Our company provides customized processing of tungsten, molybdenum, tantalum, niobium, and other products. Please contact us and we will provide you with a preferential quotation.

Post time: Mar-22-2024