Factory making Molybdenum Bar - Silicon Molybdenum Bar – WINNERS

Factory making Molybdenum Bar - Silicon Molybdenum Bar – WINNERS Detail:

Product Description

▎Product Parameters

Silicon Molybdenum Rod resistance heating element is based on molybdenum disilicide as raw material, which has the characteristics of high temperature resistance and oxidation resistance. When used in high temperature oxidation atmosphere, a bright and dense quartz (SiO2) glass film is formed on the surface, which can protect the inner layer of silicon molybdenum rod from oxidation. Silicon molybdenum rod elements have unique high temperature oxidation resistance.

| Products name | Silicon Molybdenum Bar |

| Density | 5.6~5.8g/cm3 |

| Flexural strength | 20MPa(20℃) |

| Vickers hardness (HV) | 570kg/mm2 |

| porosity | 0.5~2.0% |

| water absorption | 0.5% |

| Thermal elongation | 4% |

| emissivity | 0.7~0.8(800~2000℃) |

▎Application

Silicon molybdenum rod products are widely used in metallurgy, steel making, glass, ceramics, refractory materials, crystals, electronic components, semiconductor materials research, manufacturing and other fields, especially for high-performance precision ceramics, high-grade artificial crystals, precision structures Production of cermets, glass fibers, optical fibers and high-grade alloy steels.

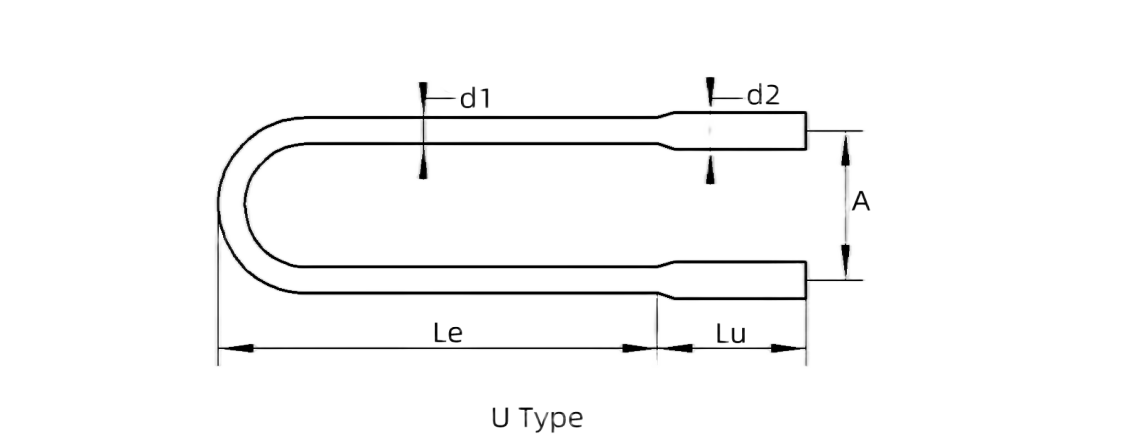

▎Product Specifications

|

Hot end diameterd1 |

Cold end diameterd2 |

Hot end length Le |

Cold end lengthLu |

Spacing A |

|

3mm |

6mm |

80-300mm |

80-500mm |

25mm |

|

4mm |

9mm |

80-350mm |

80-500mm |

25mm |

|

6mm |

12mm |

80-800mm |

80-1000mm |

25-60mm |

|

7mm |

12mm |

80-800mm |

80-1000mm |

25-60mm |

|

9mm |

18mm |

100-1200mm |

100-2500mm |

40-80mm |

|

12mm |

24mm |

100-1500mm |

100-1500mm |

40-100mm |

▎Order Information

Inquiries and orders should include the following information:

☑ Model D1/ D2 / Le/ Lu/ A parameter value, Examples: U Shape, Material Grade 1800, D1=3mm, D2=6mm, Le=140mm, Lu=125mm, A=25mm, expressed as Specify as: MS18, U Shape, 3/6×140×125×25.

☑ W type and other styles of silicon molybdenum rods can be customized according to drawings.

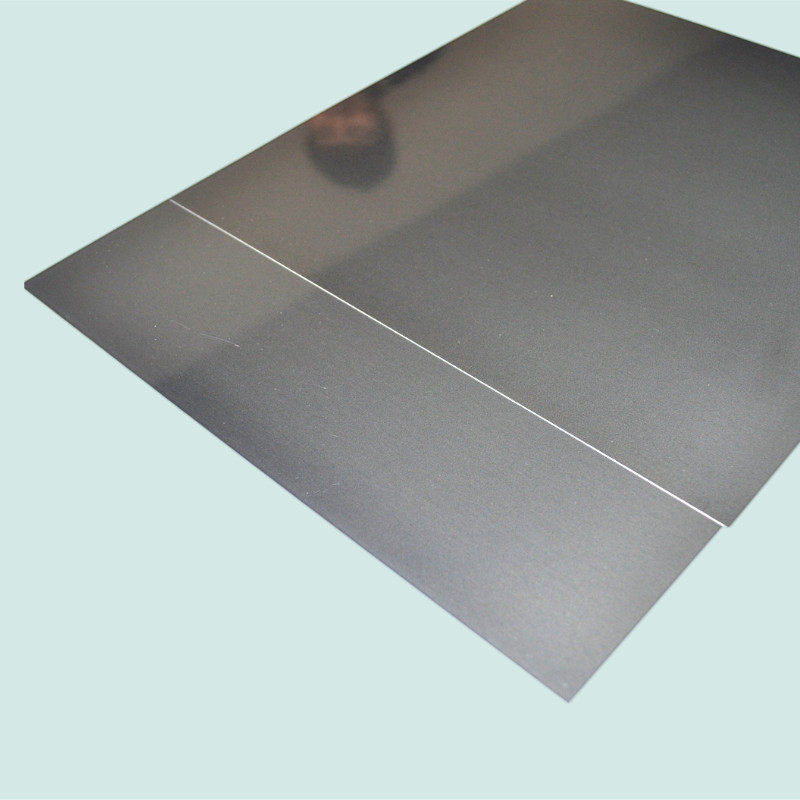

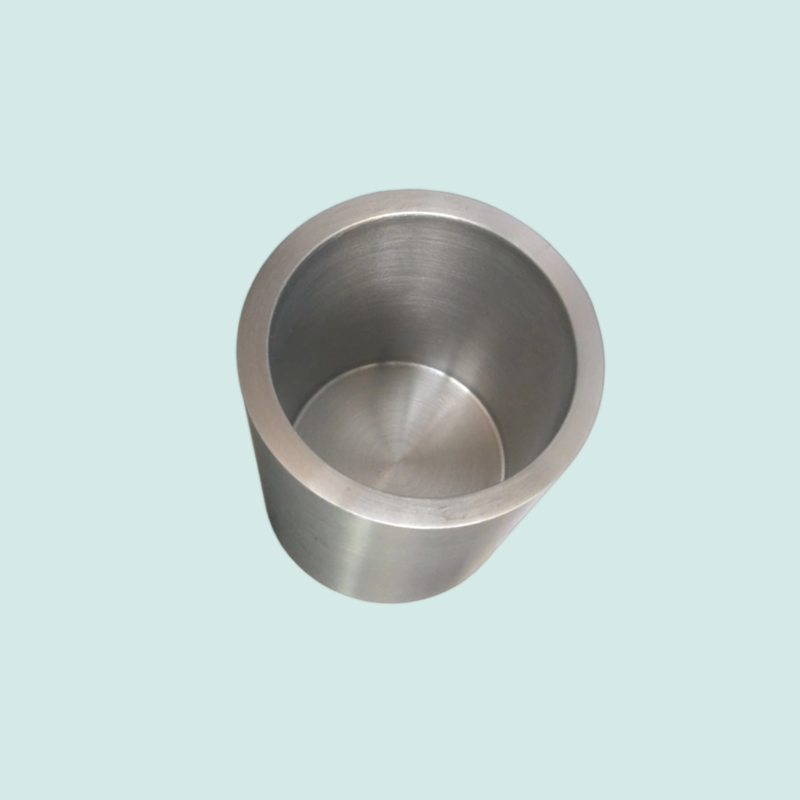

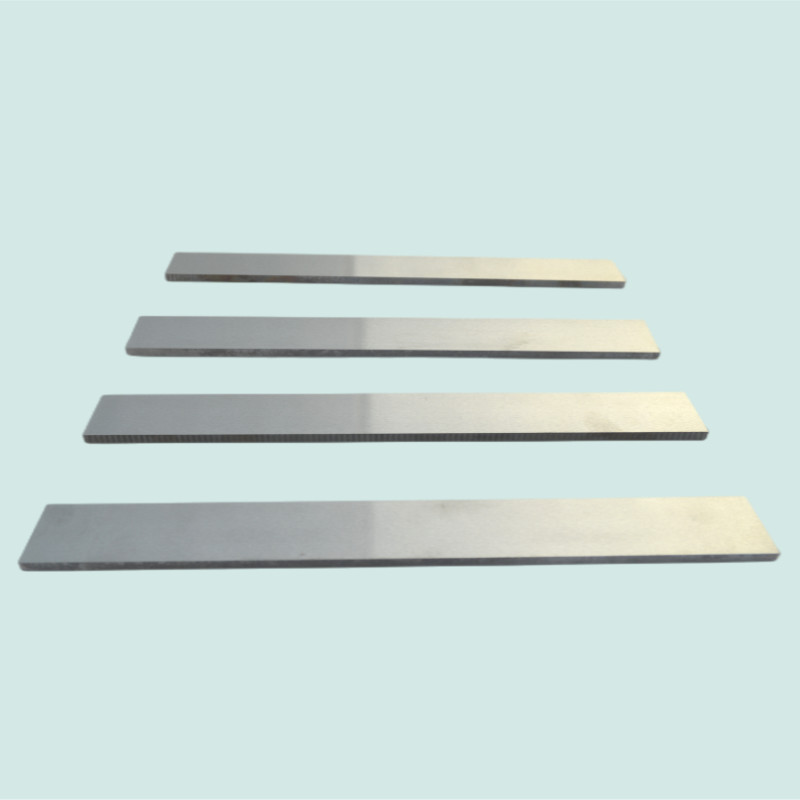

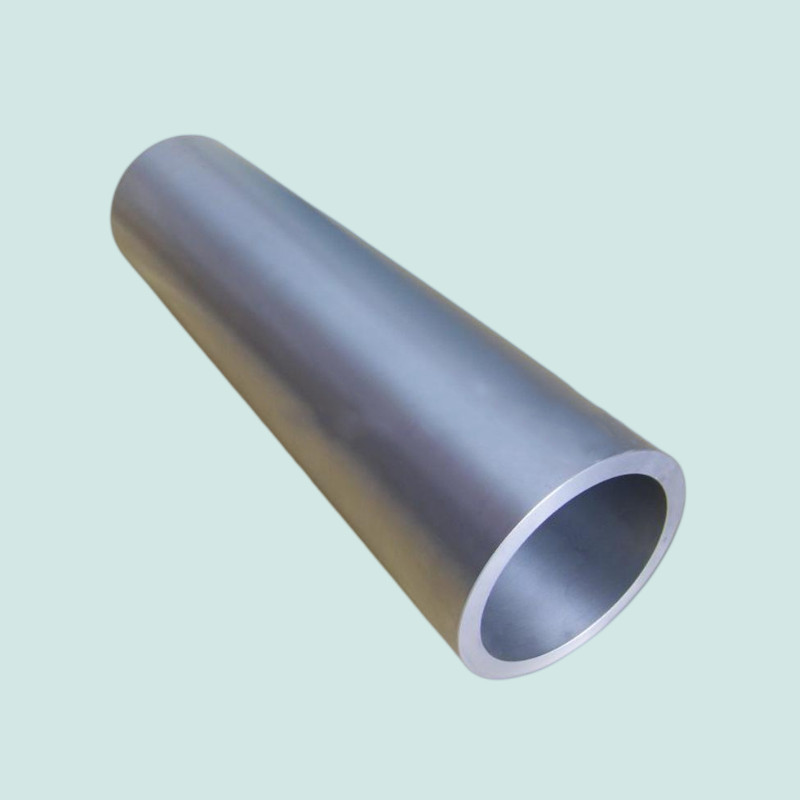

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Factory making Molybdenum Bar - Silicon Molybdenum Bar – WINNERS , The product will supply to all over the world, such as: Zambia, Plymouth, Mumbai, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have a pleasant and long terms business together!!!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.