Wholesale Discount Tungsten Wire For Vacuum Electroplating - 99.95% Pure Tungsten Sheet Plate For Sale – WINNERS

Wholesale Discount Tungsten Wire For Vacuum Electroplating - 99.95% Pure Tungsten Sheet Plate For Sale – WINNERS Detail:

Product Description

Tungsten plate rolling can be divided into hot rolling, warm rolling and cold rolling. Due to the large deformation resistance of tungsten, ordinary rolls cannot fully meet the requirements of tungsten sheet rolling, and rolls of special materials should be used. During rolling, the rolls should be preheated. According to different rolling conditions, the preheating temperature is 100~350℃. The relative density (ratio of actual density to theoretical density) of the blank can be processed when it is greater than 90%, and the processing performance is good when the blank density is 92-94%. The hot rolling billet temperature is between 1350 and 1500 ℃, and the deformation parameters of the billet are improperly selected, and the billet will be delaminated. The starting temperature of warm rolling is 1200°C, and the thickness of the hot-rolled sheet with a thickness of 8 mm can reach 0.5 mm after warm rolling.

Product Parameters

|

Products name |

Tungsten sheet |

|

Grade |

W1, W2 |

|

Purity |

≥99.95% |

|

Standard |

ASTM B760-07, GT/T 3875-2006 |

|

Flatness |

≤3% |

|

Dimensions |

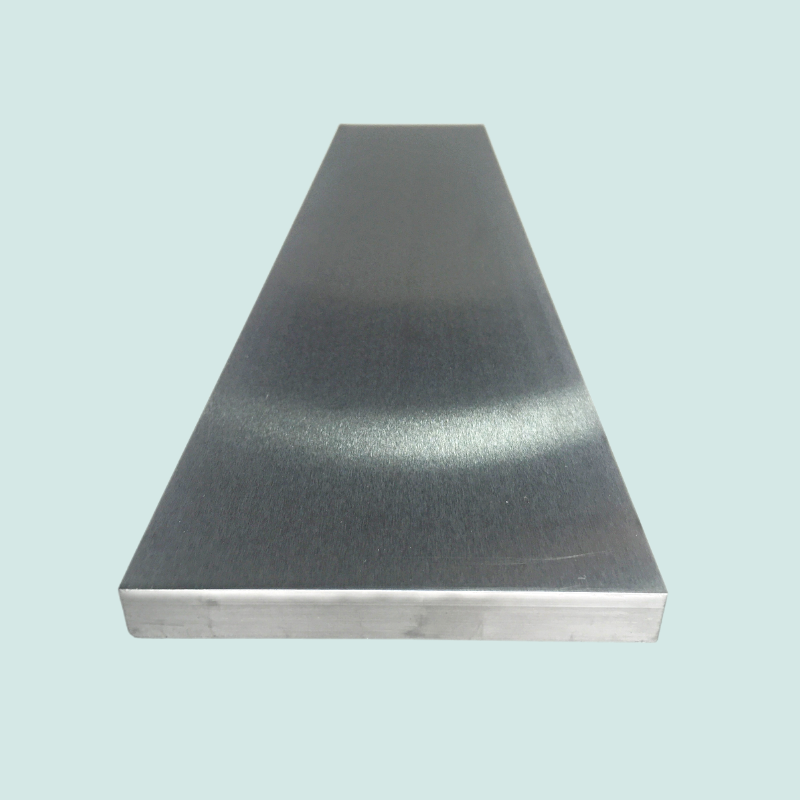

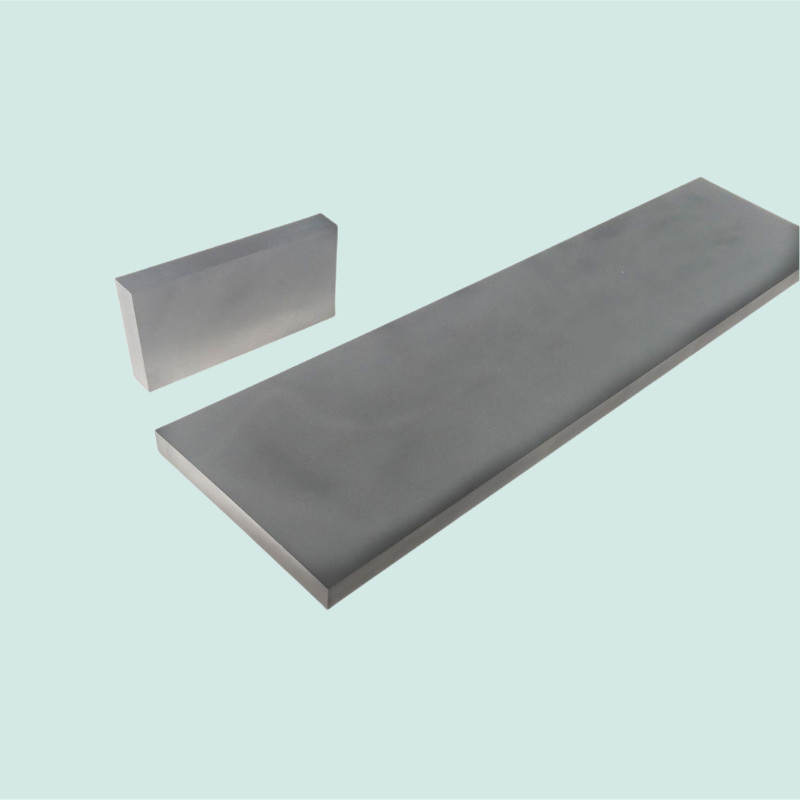

Thickness 0.1-25mm, Width≤750mm, Length≤2000mm |

|

Surface |

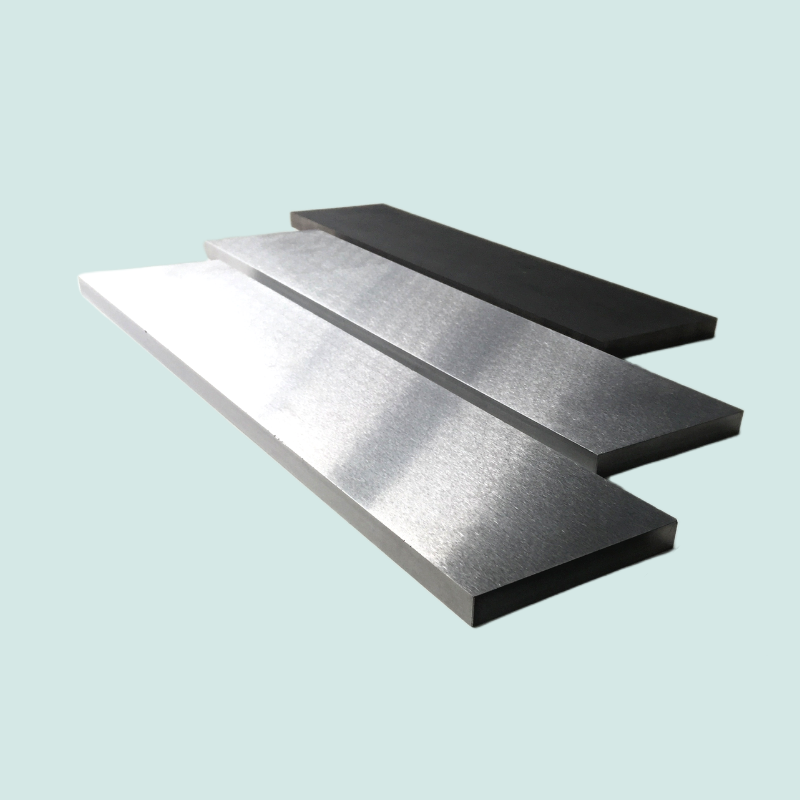

1. Alkali washed surface. 2. Electrolytic polished surface. 3. Cold rolled surface. 4. Polished surface |

Tolerance

The thickness of the tungsten plate and its allowable deviation shall meet the following requirements (unit: mm).

| Thickness | 0.1~0.2 | >0.2~0.3 | >0.3~0.4 | >0.4~0.6 | >0.6~1.0 | >1.0~2.0 | >2.0~4.0 | >4.0~6.0 | >6.0 | |

| Tolerance | ⅠClass | ±0.02 | ±0.025 | ±0.03 | ±0.04 | ±0.06 | ±0.10 | ±0.20 | ±0.30 | ±6% |

| Ⅱ Class | ±0.03 | ±0.035 | ±0.04 | ±0.05 | ±0.10 | ±0.20 | ±0.30 | ±0.40 | ±8% | |

Application

● Suitable for machining ion implanted parts.

● For making electric light source parts and electric vacuum devices.

● Heat shields and heating elements for making tungsten boats and high temperature furnaces.

● For tungsten sputtering target.

Order Information

Inquiries and orders should include the following information.

● Surface status: 1. Alkali washed surface. 2. Electrolytic polished surface. 3. Cold rolled surface. 4. Polished surface.

● Thickness, Length and Width.

● Quantity.

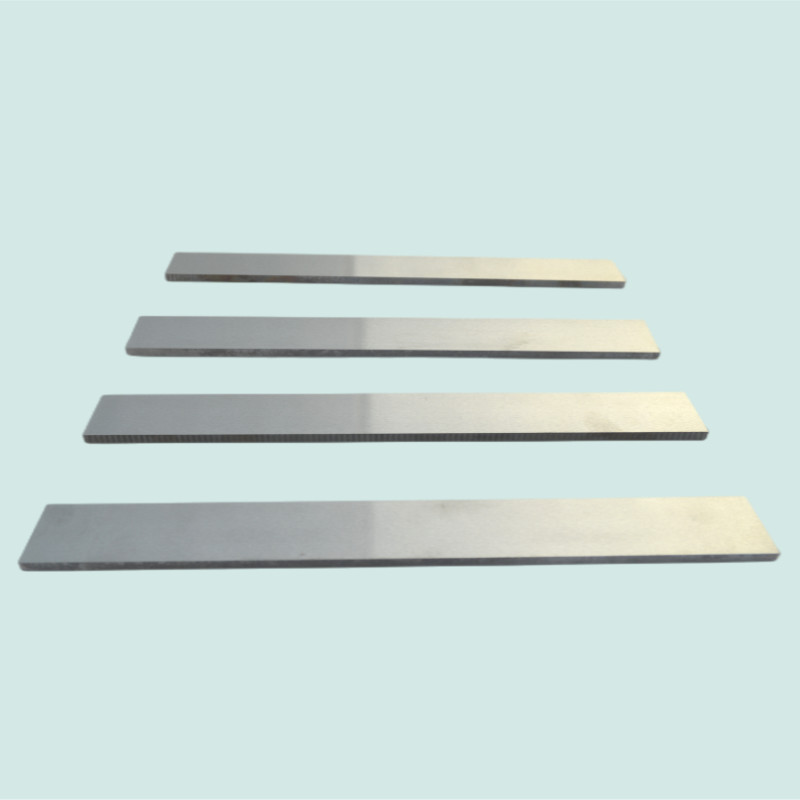

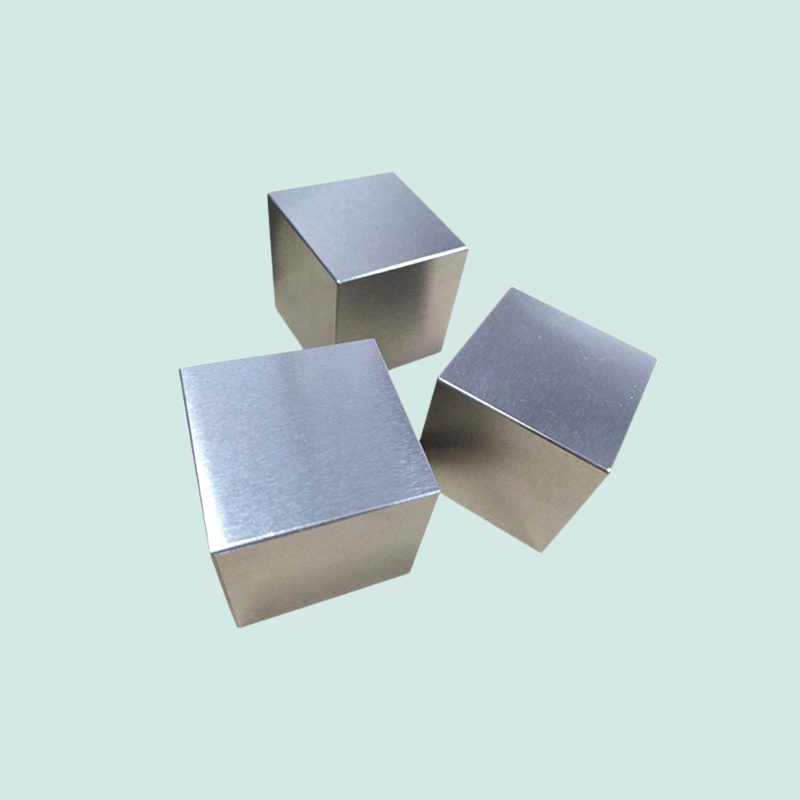

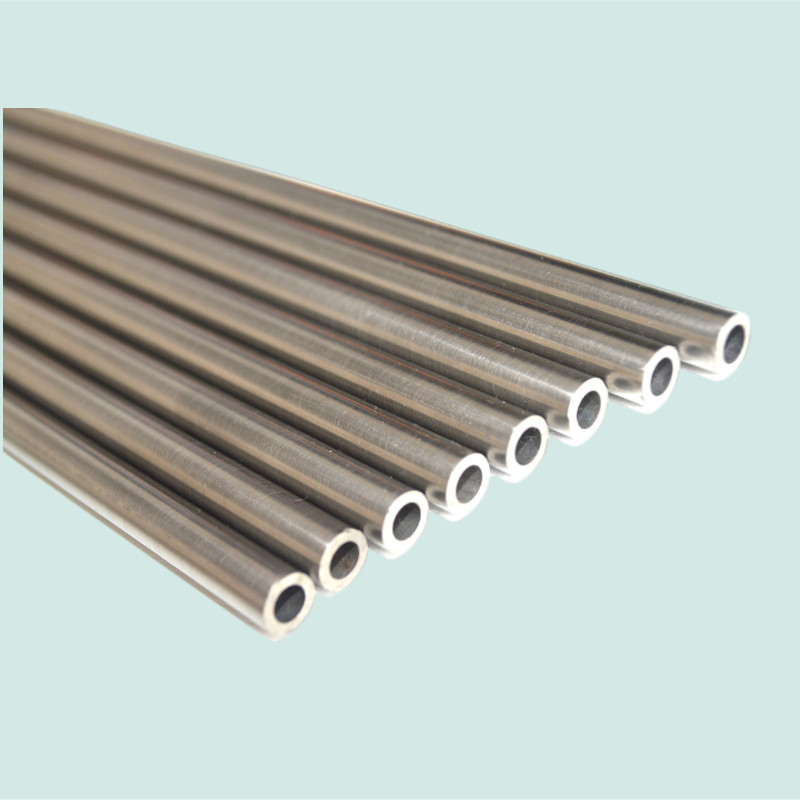

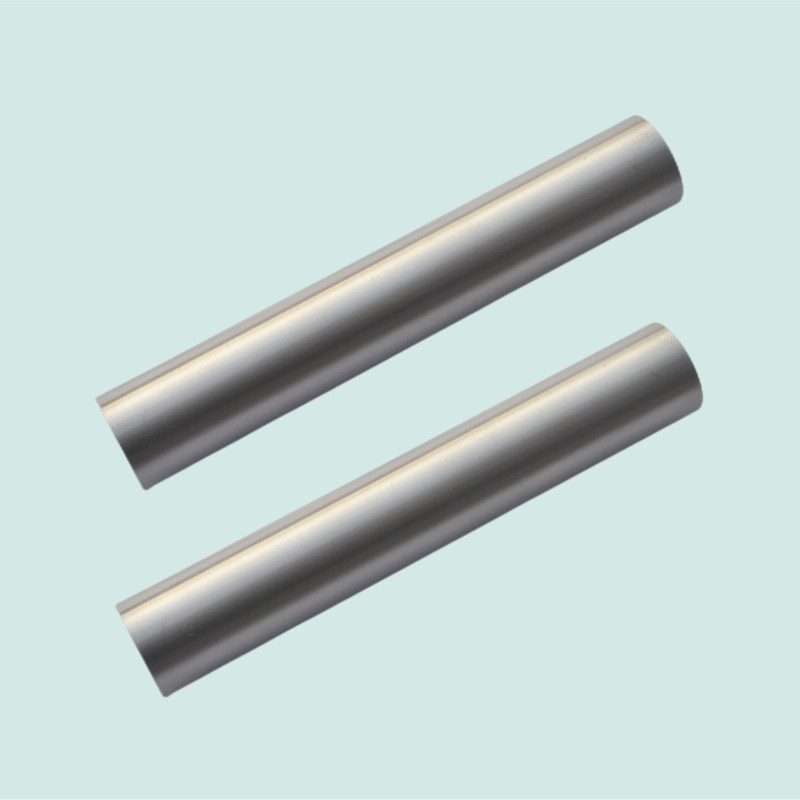

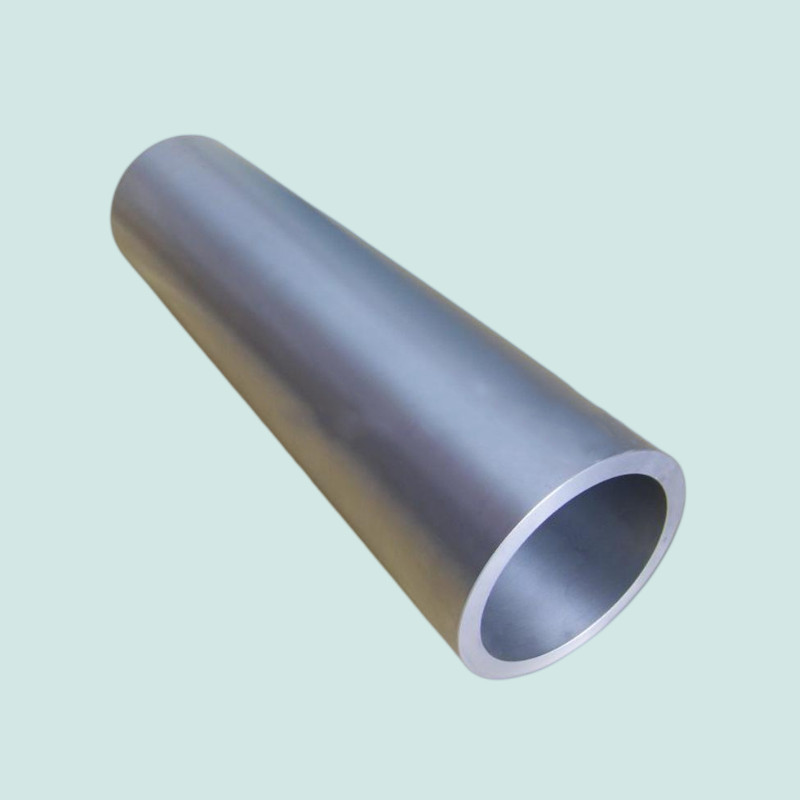

Product detail pictures:

Related Product Guide:

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Wholesale Discount Tungsten Wire For Vacuum Electroplating - 99.95% Pure Tungsten Sheet Plate For Sale – WINNERS , The product will supply to all over the world, such as: Ottawa, Bulgaria, South Korea, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.