Short Lead Time for Tungsten Rod Bar - Smelting Tungsten Crucibles Wolfram Liner Supplier – WINNERS

Short Lead Time for Tungsten Rod Bar - Smelting Tungsten Crucibles Wolfram Liner Supplier – WINNERS Detail:

Product Description

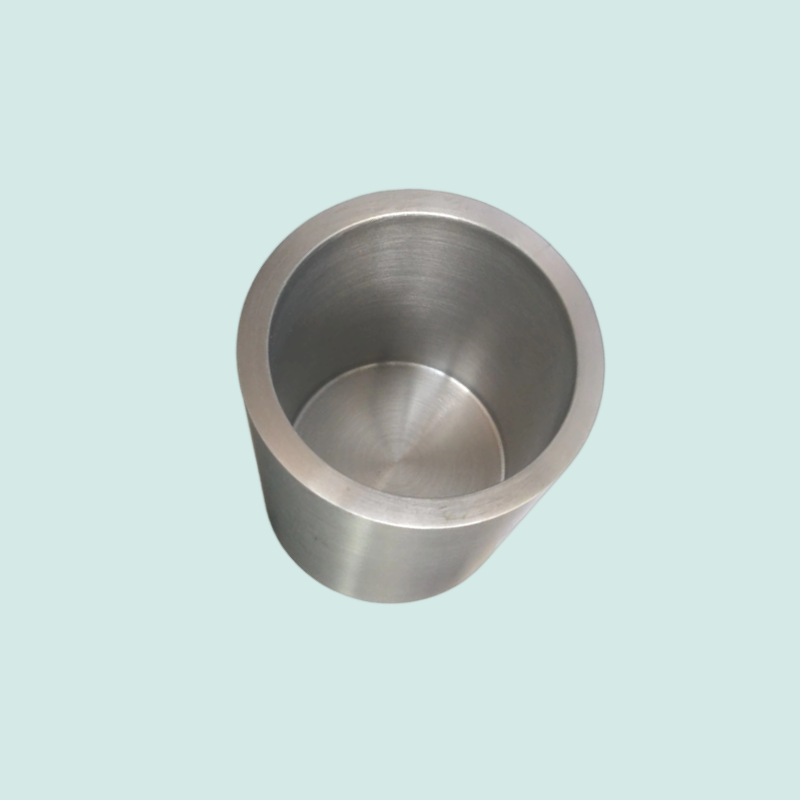

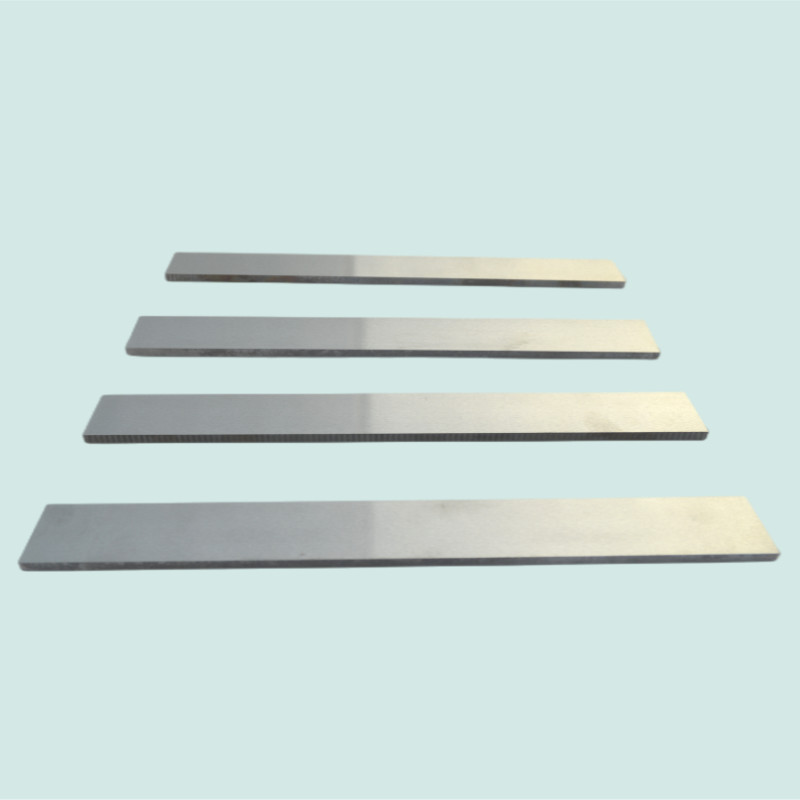

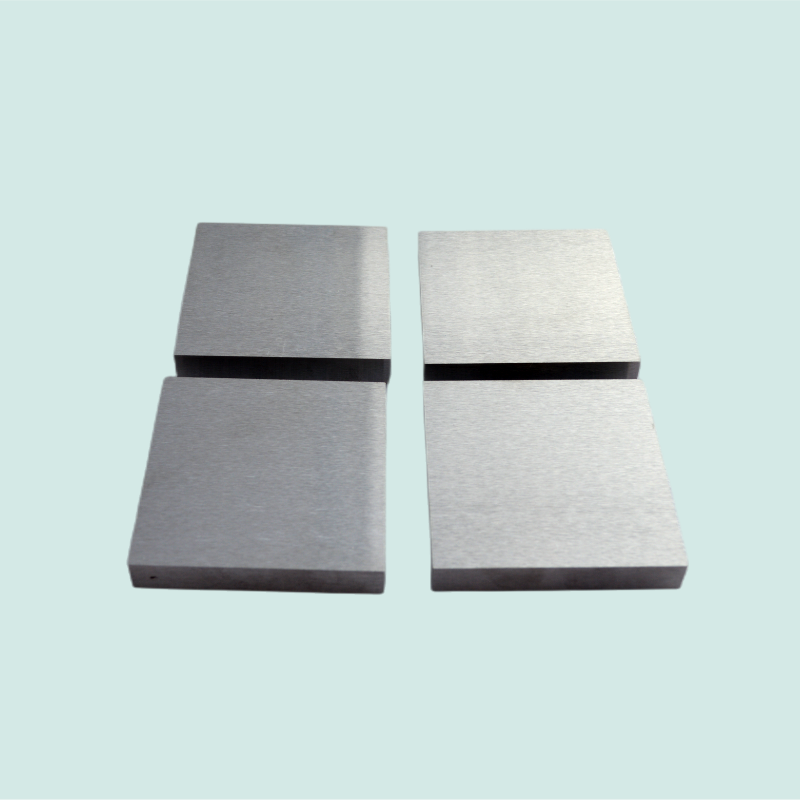

Tungsten crucibles are mainly divided into sintering (applied to powder metallurgy technology), stamping and spinning. The tungsten rod is turned and formed (generally smaller in size), and there are many kinds of welding forming. It is made of pure tungsten plate, tungsten sheet and pure tungsten rod through the corresponding process. Since the melting point of tungsten is as high as 3410 °C, tungsten crucibles are widely used in core containers in industrial furnaces such as sapphire single crystal growth furnaces, quartz glass melting furnaces, and rare earth smelting furnaces. The working temperature environment used is generally above 2000 °C. Especially for sapphire single crystal growth furnaces, tungsten crucibles with high purity, high density, no internal cracks, accurate size, smooth inner and outer walls, Decrystalline sticking to the pan and service life play a key role.

Winners Metals can provide high temperature pure tungsten crucibles in various sizes, and can provide customized crucible sizes with short lead times.

Product Parameters

|

Product name |

Tungsten crucible |

|

Grade |

W1, W2 |

|

Density |

≥18.5g/cm³ |

|

Purity |

≥99.95% |

|

Process technology |

Sintering, Punch, Spun, machine |

|

Operating temperature |

<2400 |

Available Size

|

Outer diameter (mm) |

Wall thickness (mm) |

Length (mm) |

|

Φ30~50 |

2~10 |

<1300 |

|

Φ50~100 |

3~15 |

|

|

Φ100~150 |

3~15 |

|

|

Φ150~200 |

5~20 |

|

|

Φ200~300 |

8~20 |

|

|

Φ300~400 |

8~30 |

|

|

Φ400~450 |

8~30 |

|

|

Φ450~500 |

8~30 |

Application

● Rare earth smelting.

● Evaporation coating.

● Quartz glass.

● Electronic spraying.

● Sapphire Crystal growth.

Order Information

Inquiries and orders should include the following information.

● Material.

● Drawing or size.

● Quantity.

Product detail pictures:

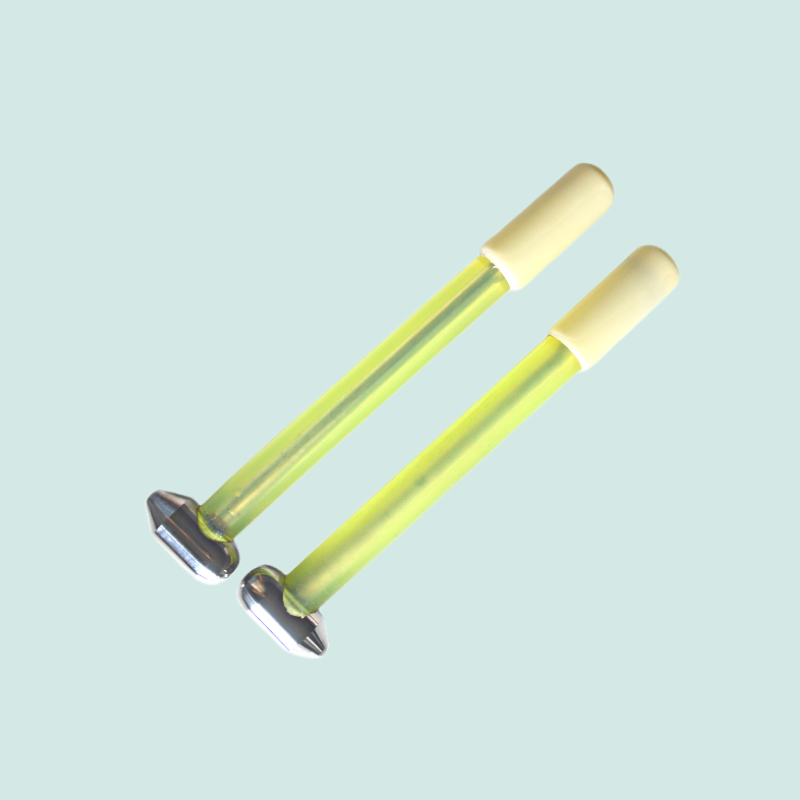

Related Product Guide:

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is "You come here with difficulty and we provide you with a smile to take away" for Short Lead Time for Tungsten Rod Bar - Smelting Tungsten Crucibles Wolfram Liner Supplier – WINNERS , The product will supply to all over the world, such as: Buenos Aires, Belize, Liverpool, We have to continue to uphold the "quality, comprehensive, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class products and improve service welcome overseas customers patrons.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.