Renewable Design for Titanium Diaphragm - Titanium and Titanium Alloy Tube – WINNERS

Renewable Design for Titanium Diaphragm - Titanium and Titanium Alloy Tube – WINNERS Detail:

Product Description

The advantage of titanium tube

1. Titanium tube has high specific strength. The density of titanium alloy is generally about 4.5g/cm3, which is only 60% of steel. The strength of pure titanium is close to that of ordinary steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials, and parts and components with high unit strength, good rigidity and light weight can be produced. At present, titanium alloys are used in aircraft engine components, skeletons, skins, fasteners and landing gear.

2. Titanium tube has good corrosion resistance. Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is much better than stainless steel; its resistance to pitting corrosion, acid corrosion, and stress corrosion is particularly strong; it is resistant to alkali, chloride, chlorine, organic substances, nitric acid, sulfuric acid etc. have excellent corrosion resistance.

3. The low temperature performance of titanium tube is good. Titanium alloys can still maintain their mechanical properties at low and ultra-low temperatures. Titanium alloys with good low temperature performance and extremely low interstitial elements, such as TA7, can maintain a certain plasticity at -253 °C. Therefore, titanium alloy is also an important low-temperature structural material.

Product Parameters

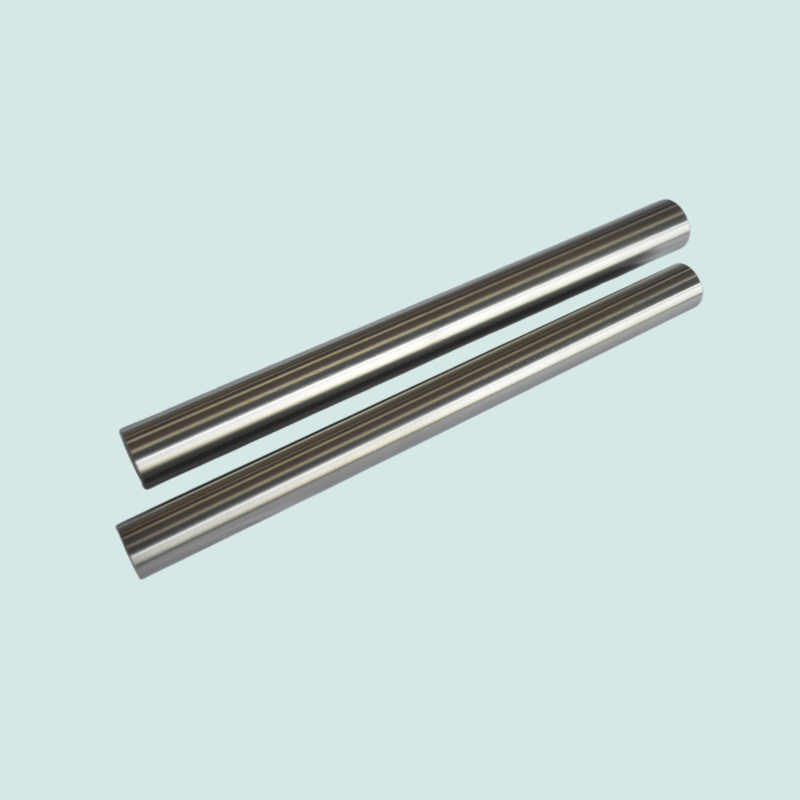

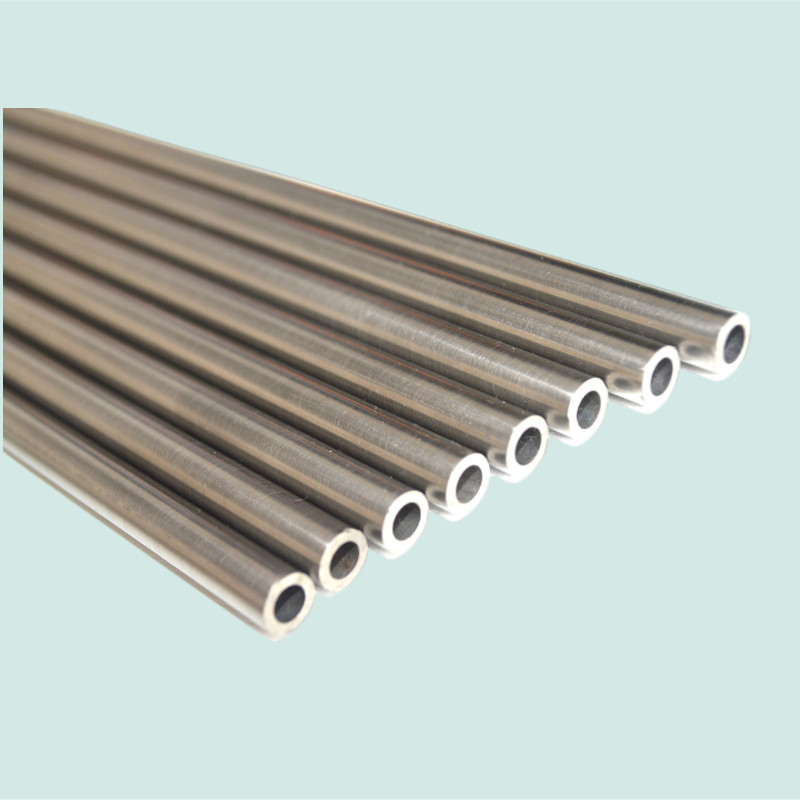

| Products name | Titanium tube and titanium alloy tube |

| Standard | GB/T3624-2010, GB/T3625-2007 ASTM 337, ASTM 338 |

| Grade | TA0, TA1, TA2, TA10, TC4, GR1, GR2, GR5 |

| Density | 4.51g/cm³ |

| Status | Annealing |

| Surface | Pickling,polishing |

| MOQ | 10Kg |

Application

● Military industry

● Aerospace

● Marine industry

● Chemical

● In medicine

Order Information

Inquiries and orders should include the following information

● Diameter, wall thickness, Length of the Titanium tubes

● Grade( Gr1, Gr2, Gr5, etc.)

● Surface treatment( Pickling or Polishing)

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for Renewable Design for Titanium Diaphragm - Titanium and Titanium Alloy Tube – WINNERS , The product will supply to all over the world, such as: India, Egypt, New Zealand, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our goods in China!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.