R05200 Pure tantalum tube pipe manufacture

Product Description

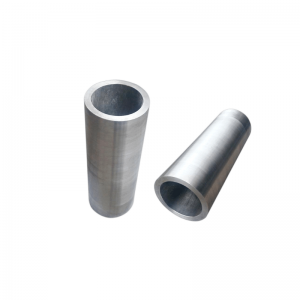

Tantalum tube

Tantalum tubes have many uses. Because tantalum has the characteristics of high melting point, corrosion resistance and good cold working performance, it is widely used in aviation and aerospace industry, high temperature technology, atomic energy industry and chemical industry. It is mainly used to make supersonic aircraft, rocket engines. Parts of the spacecraft combustion chamber, high temperature resistant furnace parts, parts resistant to nitric acid, sulfuric acid, hydrochloric acid corrosion, etc.

Product Parameters

|

Products name |

Tantalum tube |

|

Standard |

GB/T8182-2008, ASTM B521 |

|

Grade |

Ta 1, Ta 2 |

|

Density |

16.67g/cm³ |

|

Purity |

≥99.95% |

|

Technology process |

Extrusion, Tube Forming, Welding |

|

Type |

Seamless pipe Welded pipe |

Product specificatione

| Outer diameter (mm) | Wall thickness (mm) | Length (mm) |

| φ2.0~φ100 | ≥0.3 | L≤6000 |

Note: Other specifications can be customized.

Appliction

■ Chemical reaction vessels and heat exchangers, pipes, condensers, bayonet heaters, helical coils, U-tubes.

■ Thermocouple and its protection tube.

■ Liquid metal containers and pipes, etc.

■ Tantalum tube for cutting the tantalum ring for jewelry field.

The difference between seamless tantalum tube

and welded tantalum tube.

Seamless tantalum tube

Advantages

1: Small size pipes and capillary pipes can be produced.

2: Good flexibility, suitable for producing products with small batches and many specifications.

3: The performance of each part of the pipe is uniform.

Disadvantages

1: The uniformity of wall thickness is difficult to control.

2: The production cycle is long and the finished product rate is low.

3: The equipment is complex and the investment is large.

4: It is difficult to produce large diameter pipes.

Welded tantalum tube

Advantage

1: Uniform wall thickness and good inner surface quality.

2: High production efficiency, Low cost.

3: Easy to produce large diameter pipes.

4: Short production cycle.

5: Product quality is easy to control.

Disadvantages

1: Poor flexibility, it is not suitable to produce products with many specifications and small batches.

2: Welds are often the weak link.

3: Weld seam cleaning is more difficult.

4: Ovality is not easy to control.

5: High requirements for the dimensional accuracy of the strip used.

Order Information

Inquiries and orders should include the following information:

☑ Diameter, wall thickness, length of the tantalum tubing.

☑ Welded Tantalum Tube, Seamless Tantalum Tube.

☑ Quantity.

We can also produce capillary tantalum tubes, Click to view details.

Contact us 【Amanda│Sales Manager】 0086 156 1977 8518 (Whatsapp/Wechat)