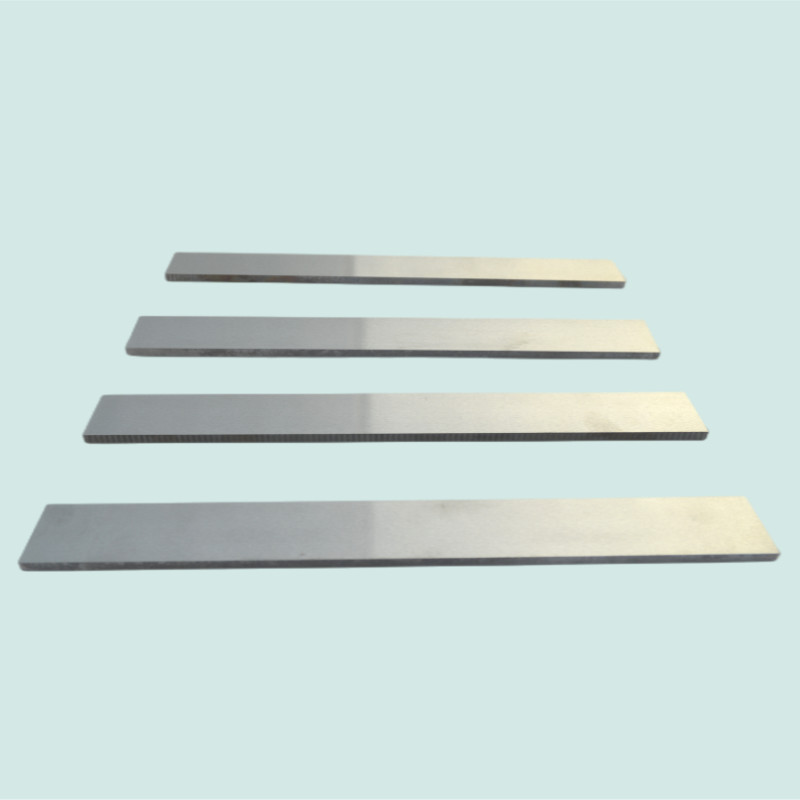

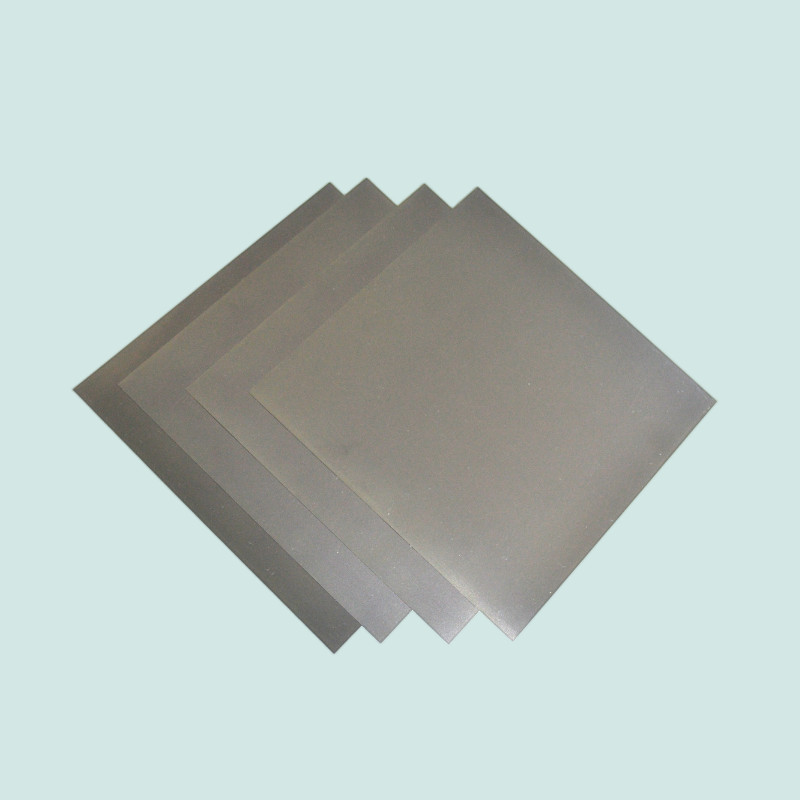

Hot New Products Tungsten Carbide Crushed - 99.95% Pure Tungsten Sheet Plate For Sale – WINNERS

Hot New Products Tungsten Carbide Crushed - 99.95% Pure Tungsten Sheet Plate For Sale – WINNERS Detail:

Product Description

Tungsten plate rolling can be divided into hot rolling, warm rolling and cold rolling. Due to the large deformation resistance of tungsten, ordinary rolls cannot fully meet the requirements of tungsten sheet rolling, and rolls of special materials should be used. During rolling, the rolls should be preheated. According to different rolling conditions, the preheating temperature is 100~350℃. The relative density (ratio of actual density to theoretical density) of the blank can be processed when it is greater than 90%, and the processing performance is good when the blank density is 92-94%. The hot rolling billet temperature is between 1350 and 1500 ℃, and the deformation parameters of the billet are improperly selected, and the billet will be delaminated. The starting temperature of warm rolling is 1200°C, and the thickness of the hot-rolled sheet with a thickness of 8 mm can reach 0.5 mm after warm rolling.

Product Parameters

|

Products name |

Tungsten sheet |

|

Grade |

W1, W2 |

|

Purity |

≥99.95% |

|

Standard |

ASTM B760-07, GT/T 3875-2006 |

|

Flatness |

≤3% |

|

Dimensions |

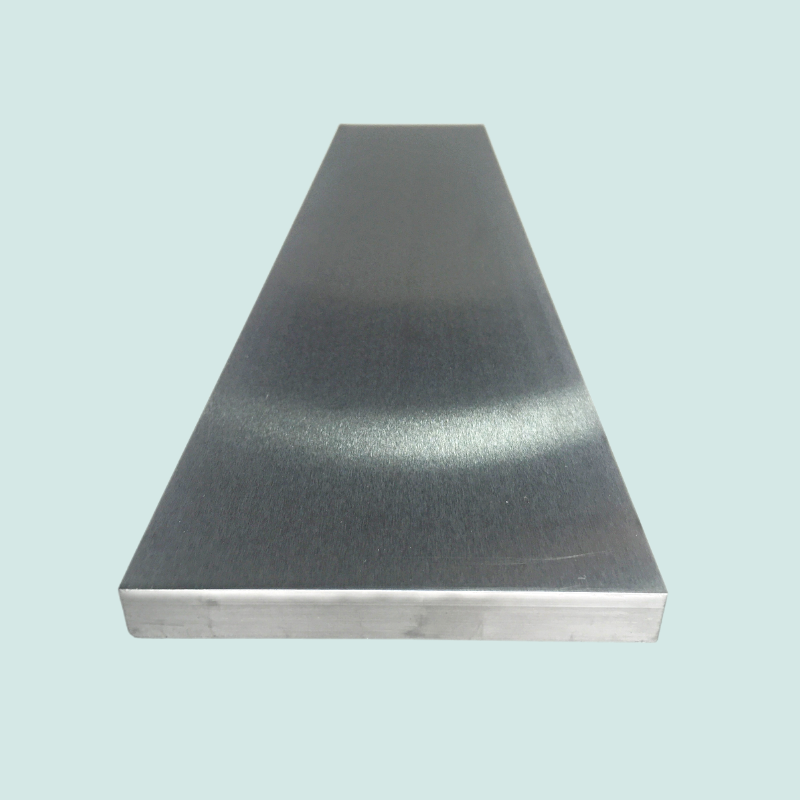

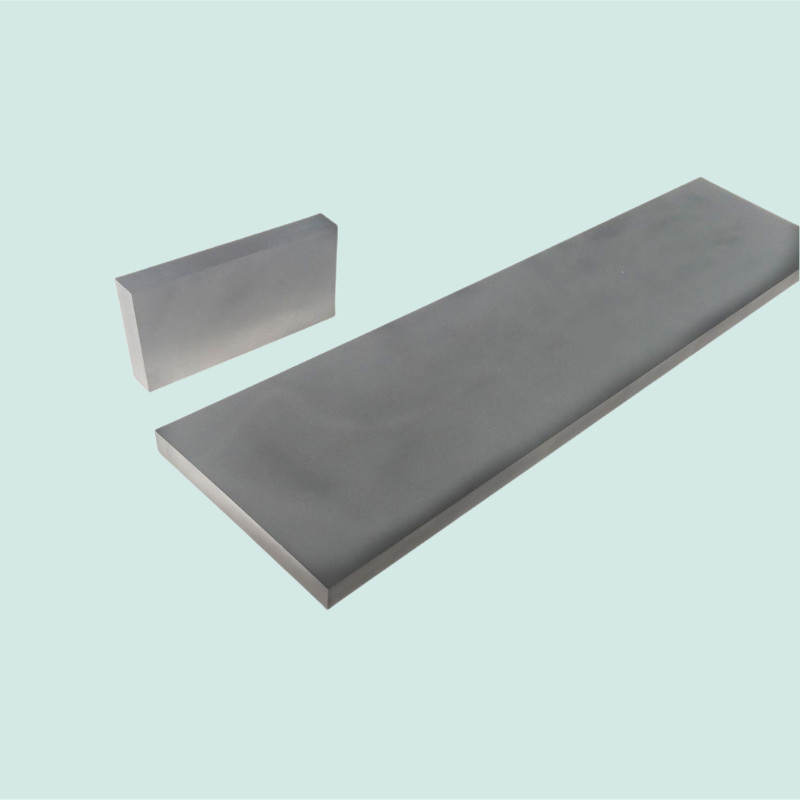

Thickness 0.1-25mm, Width≤750mm, Length≤2000mm |

|

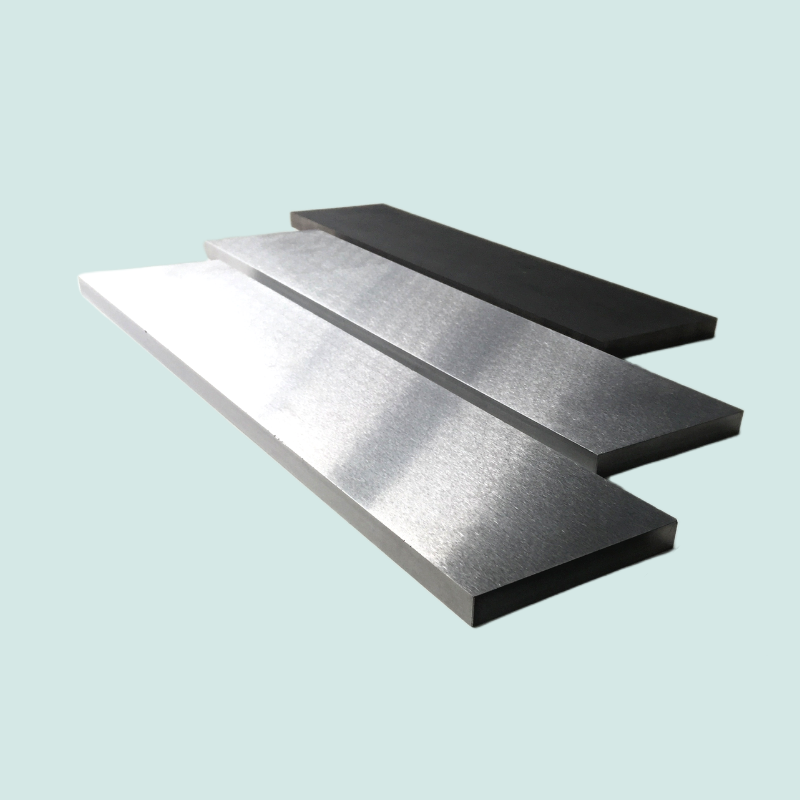

Surface |

1. Alkali washed surface. 2. Electrolytic polished surface. 3. Cold rolled surface. 4. Polished surface |

Tolerance

The thickness of the tungsten plate and its allowable deviation shall meet the following requirements (unit: mm).

| Thickness | 0.1~0.2 | >0.2~0.3 | >0.3~0.4 | >0.4~0.6 | >0.6~1.0 | >1.0~2.0 | >2.0~4.0 | >4.0~6.0 | >6.0 | |

| Tolerance | ⅠClass | ±0.02 | ±0.025 | ±0.03 | ±0.04 | ±0.06 | ±0.10 | ±0.20 | ±0.30 | ±6% |

| Ⅱ Class | ±0.03 | ±0.035 | ±0.04 | ±0.05 | ±0.10 | ±0.20 | ±0.30 | ±0.40 | ±8% | |

Application

● Suitable for machining ion implanted parts.

● For making electric light source parts and electric vacuum devices.

● Heat shields and heating elements for making tungsten boats and high temperature furnaces.

● For tungsten sputtering target.

Order Information

Inquiries and orders should include the following information.

● Surface status: 1. Alkali washed surface. 2. Electrolytic polished surface. 3. Cold rolled surface. 4. Polished surface.

● Thickness, Length and Width.

● Quantity.

Product detail pictures:

Related Product Guide:

With reliable quality process, good reputation and perfect customer service, the series of products produced by our company are exported to many countries and regions for Hot New Products Tungsten Carbide Crushed - 99.95% Pure Tungsten Sheet Plate For Sale – WINNERS , The product will supply to all over the world, such as: Sri Lanka, kazakhstan, Bahamas, We expect to provide products and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

A good manufacturers, we have cooperated twice, good quality and good service attitude.