High Quality Molybdenum Bar Suppliers - Pure Molybdenum Wire Manufacture – WINNERS

High Quality Molybdenum Bar Suppliers - Pure Molybdenum Wire Manufacture – WINNERS Detail:

Product Description

Molybdenum has a very high melting point, low thermal expansion and high thermal conductivity, so it is used in many different industries.

Molybdenum wire is divided into spraying molybdenum wire, wire cutting molybdenum wire and electric light source molybdenum wire according to the purpose. General molybdenum wire processing plants use ammonium molybdate or high-purity molybdenum oxide as raw materials, and have the following production capacity: 1. Molybdenum powder production: use ammonium molybdate or high-purity molybdenum oxide as raw materials to reduce molybdenum powder. 2. Molybdenum rod production: Molybdenum powder is isostatically pressed and then sintered into molybdenum rods at high temperature. 3. Thick molybdenum wire: The molybdenum bar is rolled at high temperature into thick wire of 5-6mm. 4. Thin molybdenum wire: The thick wire of 5-6mm is stretched one or more times to finally produce the size required by the customer.

Product Parameters

|

Products name |

Molybdenum wire |

|

Grade |

Mo1, MoLa |

|

Standard |

GB/T 4181-2017 |

|

Purity |

99.95%, 99.92% |

|

Density |

10.2g/cm³ |

|

MOQ |

1Kg |

|

Surface |

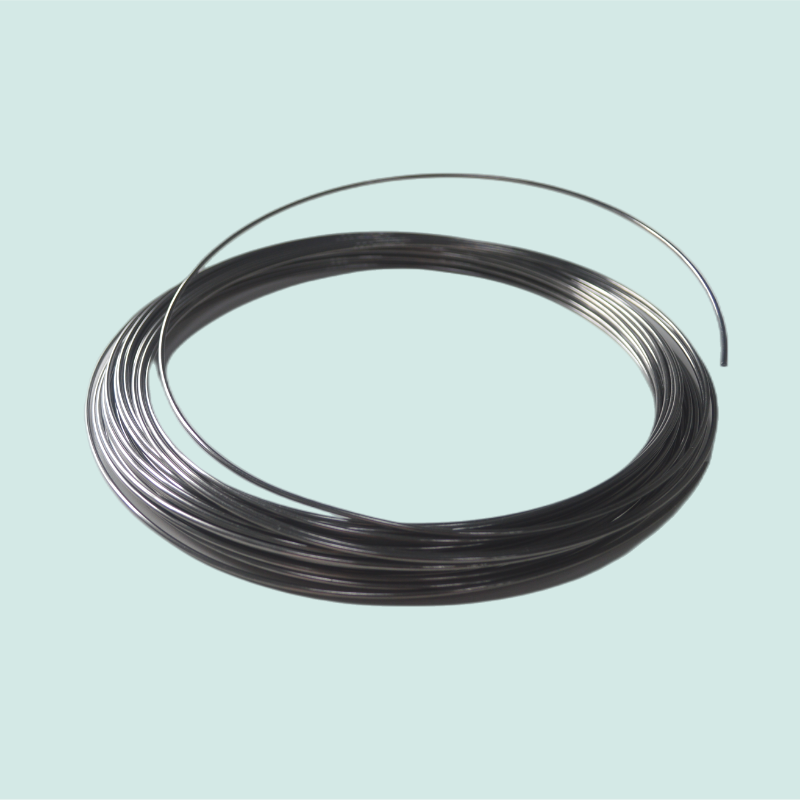

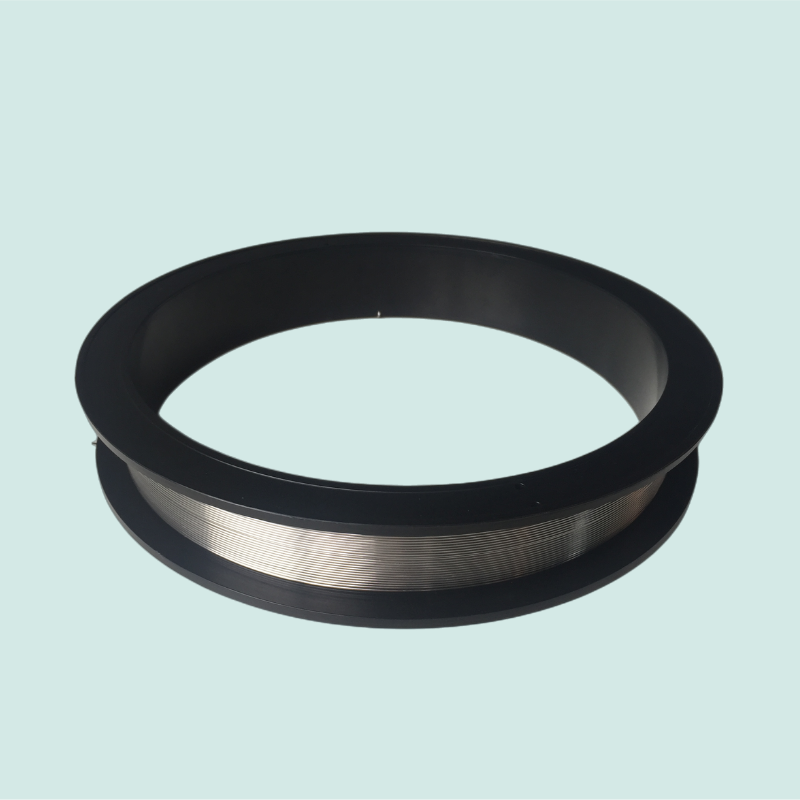

Black wire, bright wire |

|

Technology process |

drawing, polishing |

|

Application |

Spray molybdenum wire, EDM cutting wire, molybdenum wire for high temperature furnace |

Application

● Forming material Cutting, H2 Furnaces, Heater Rod Guide Rod Hooks, Mandrels, Wires, etc.

● High temperature brackets, guide rods, heating rods in the furnace, etc.

● Molybdenum wire is mainly used in high temperature thermal field of molybdenum furnace and tube socket.

● EDM wire cutting.

● Spray Molybdenum Wire Automotive Industry.

Product Specifications

|

Application field |

Diameter |

|

EDM wire cutting |

0.16mm, 0.18mm, 0.2mm |

|

Spray molybdenum wire |

1.4mm, 2.0mm, 2.5mm, 3.0mm, 3.17mm |

|

Heating elements of the vacuum furnace |

0.5mm, 0.6mm, 1.0mm, 2.0mm, 3.0mm, 6.35mm |

EDM Order Information

Inquiries and orders should include the following information.

● Surface: Back or bright wire.

● Diameter, weight or Length.

● Other special demand.

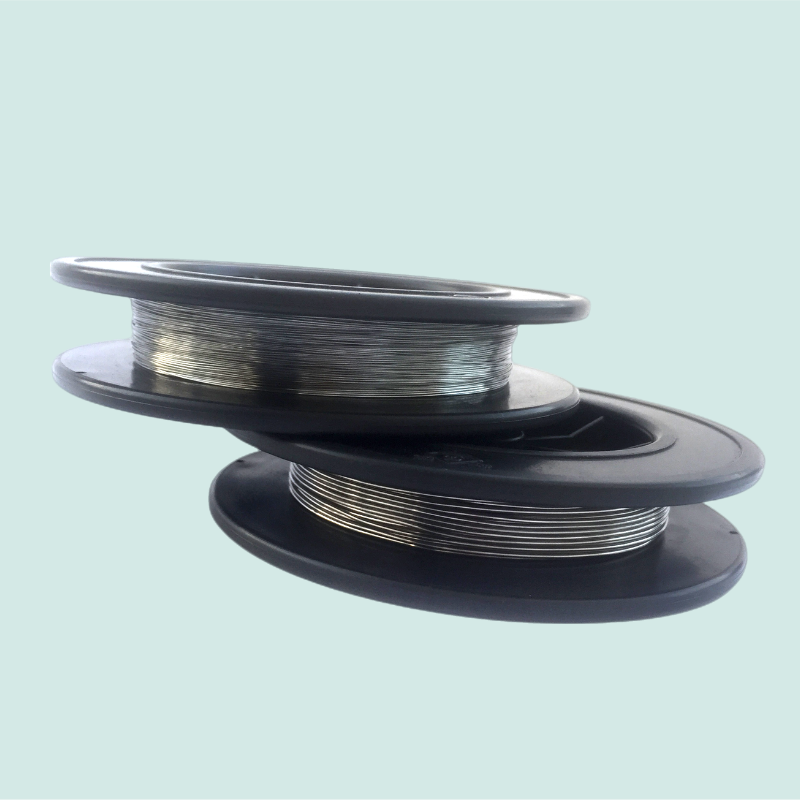

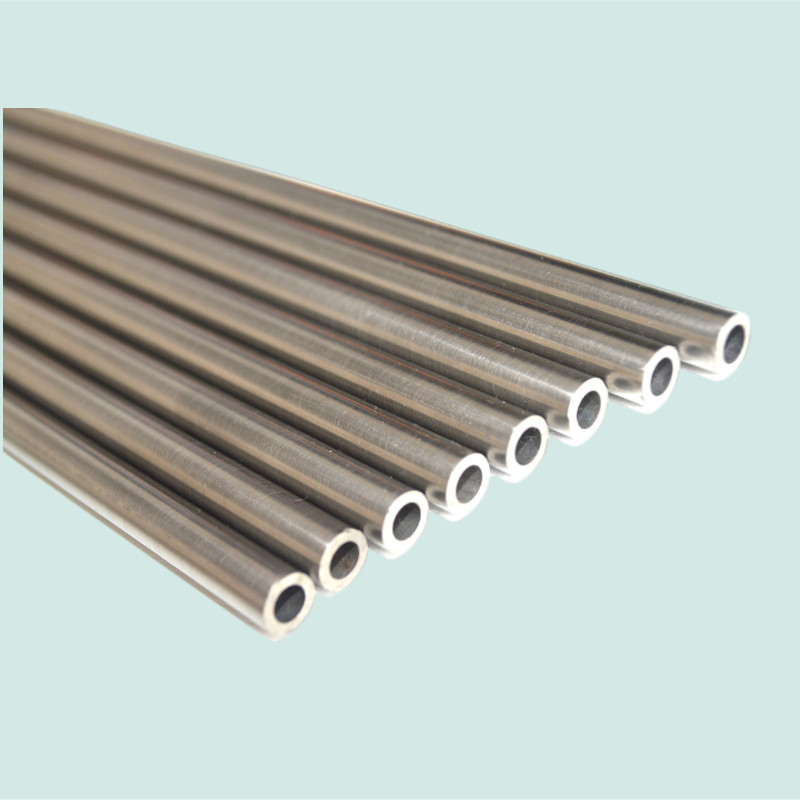

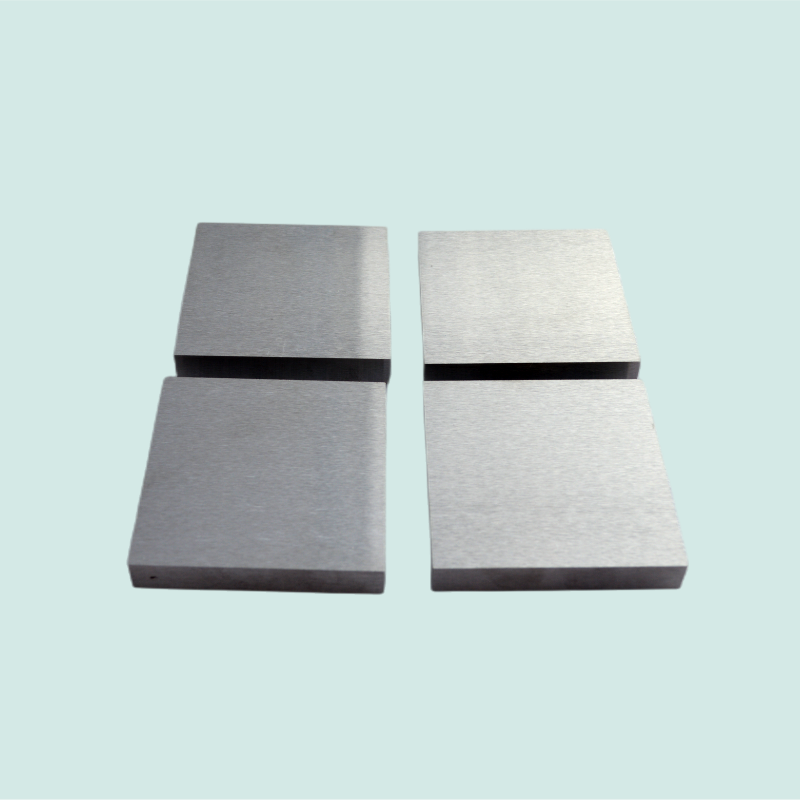

Product detail pictures:

Related Product Guide:

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for High Quality Molybdenum Bar Suppliers - Pure Molybdenum Wire Manufacture – WINNERS , The product will supply to all over the world, such as: Vietnam, Moscow, Guatemala, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.