Good Quality Niobium Bar Stock - Polish 99.95% Pure Niobium Tube And Pipe – WINNERS

Good Quality Niobium Bar Stock - Polish 99.95% Pure Niobium Tube And Pipe – WINNERS Detail:

Product Description

Niobium tube and niobium alloy tube have the characteristics of high melting point, corrosion resistance, good cold working performance, etc., and are widely used in chemical industry, electronic industry, aviation and aerospace industry. They are mainly used as structural materials for high pressure sodium lamps, aviation and aerospace engines, chemical processes of reactor vessels, heat exchanger tubes, reactor internals and envelope materials, etc. Niobium-zirconium alloys are manufactured into capillaries to supply sodium lamp manufacturing.

Product Parameters

|

Products name |

Niobium tube |

|

Standard |

ASTM B394 |

|

Grade |

Nb1, Nb2, RO4200 |

|

Purity |

99.95% |

|

Density |

8.57g/cm3 |

|

MOQ |

1Kg |

|

Melting point |

2468℃ |

|

Type |

Seamless tube, Welded tube |

|

Technology process |

Annealed, Cold Rolled, Cold Drawn |

Ingredient Description

|

Ingredient |

||||||||||||

|

Grade |

Main |

Other impurities (max) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

Nb1 |

Bal |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.05 |

0.012 |

0.0035 |

0.0012 |

0.003 |

|

Nb2 |

Bal |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.07 |

0.015 |

0.0050 |

0.0015 |

0.005 |

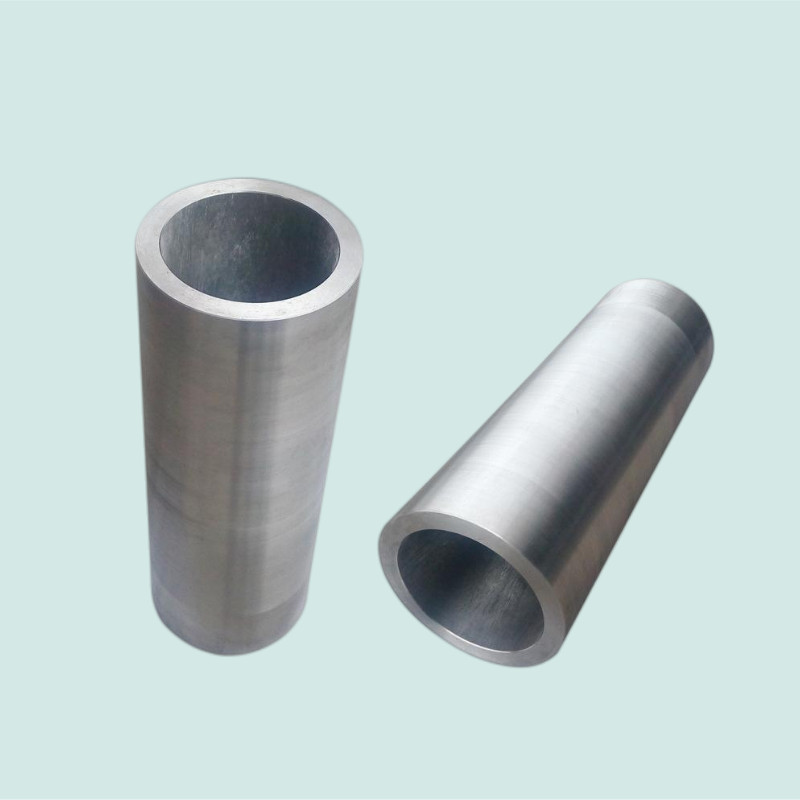

Product Specifications

Diameter: φ2.0-100mm

Thickness: 0.2-5.0mm

Length: 200mm-8000mm

Niobium capillary specifications: outer diameter Φ0.2~Φ8mm, wall thickness 0.015~0.5mm.Other product specifications can be customized.

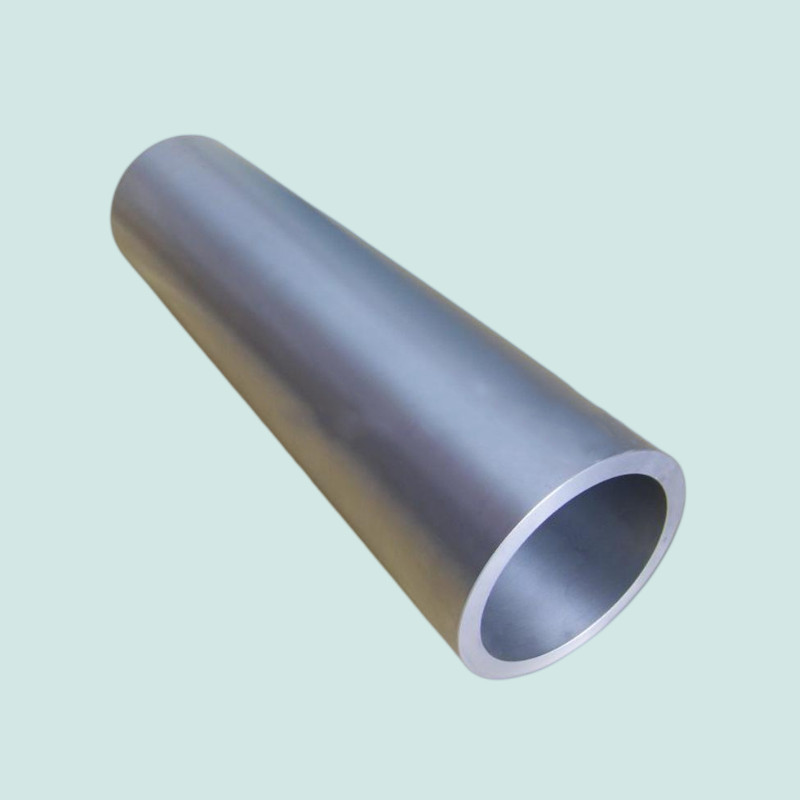

Product Appearance Standard

The surface of the inner and outer tube walls presents a uniform metallic luster, without oxidation, hydrogenation discoloration, scratches and deformations.

Application

● Niobium capillary tubing and niobium zirconium capillary tubing is often used in high pressure sodium lamp production.

● Use as additive to high strength low alloy steel and stainless steel for oil.

● Chemical processing equipment.

● Cathode protection systems for large steel structures.

Order Information

Inquiries and orders should include the following information.

● Outer diameter, Inner diameter or wall thickness and length of the Niobium pipe.

● Quantity.

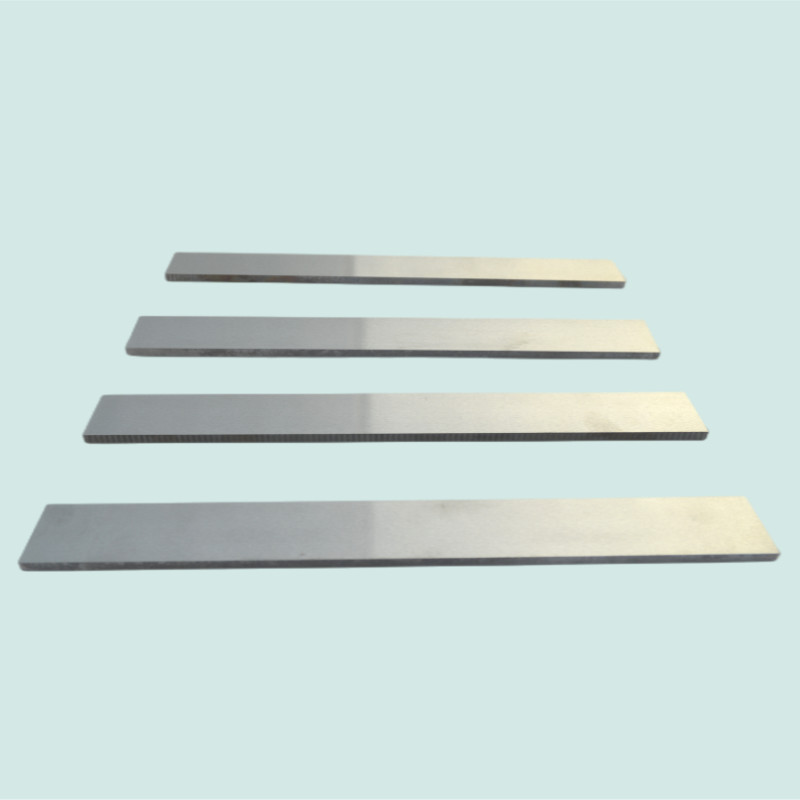

Product detail pictures:

Related Product Guide:

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for Good Quality Niobium Bar Stock - Polish 99.95% Pure Niobium Tube And Pipe – WINNERS , The product will supply to all over the world, such as: Turkey, Casablanca, panama, Over the years, with high-quality solutions, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We offer high quality product and competitive price, welcome the regular and new customers cooperate with us!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.