Flushing ring for flanged diaphragm seal systems

Product Description

Flushing rings are used with Flanged Diaphragm Seals. The main function is to flush the diaphragm to prevent the process medium from crystallizing, depositing or corroding in the sealing area, thereby protecting the seal, extending the service life of the equipment, and ensuring the reliability of the measurement or control system.

The flushing ring has two threaded ports on the side for flushing the diaphragm. The main advantage of the flushing ring is that the system can be flushed without removing the diaphragm seal from the process flange. The flushing ring can also be used for exhaust or field calibration.

Flushing rings are available in a variety of materials, including stainless steel, Hastelloy, Monel, etc., and can be selected according to the properties of the fluid and the use environment. The reasonable design and use of flushing rings can effectively protect the diaphragm sealing system in harsh industrial environments and ensure the equipment's long-term normal operation.

Where is the Flushing Ring Used?

The flushing ring is used in flanged diaphragm seal systems. It is used in industries that process or transport fluids that are viscous, corrosive or contain sediment, such as oil and gas, wastewater treatment, and food and beverage processing.

Specifications

|

Product Name |

Flushing Ring |

|

Material |

Stainless steel 316L,Hastelloy C276, Titanium, Other materials on request |

|

Size |

• DN25, DN40, DN50, DN80, DN100, DN125 (DIN EN 1092-1) • 1", 1 ½", 2", 3", 4", 5" (ASME B16.5) |

|

Number of Ports |

2 |

|

Port Connection |

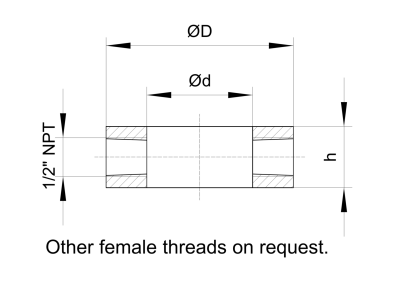

½" NPT female, other threads on request |

| Connections according to ASME B16.5 | ||||

| Size | Class | Dimension (mm) | ||

| D | d | h | ||

| 1" | 150...2500 | 51 | 27 | 30 |

| 1 ½" | 150...2500 | 73 | 41 | 30 |

| 2" | 150...2500 | 92 | 62 | 30 |

| 3" | 150...2500 | 127 | 92 | 30 |

| 4" | 150...2500 | 157 | 92 | 30 |

| 5" | 150...2500 | 185.5 | 126 | 30 |

| Connections according to EN 1092-1 | ||||

| DN | PN | Dimension (mm) | ||

| D | d | h | ||

| 25 | 16...400 | 68 | 27 | 30 |

| 40 | 16...400 | 88 | 50 | 30 |

| 50 | 16...400 | 102 | 62 | 30 |

| 80 | 16...400 | 138 | 92 | 30 |

| 100 | 16...400 | 162 | 92 | 30 |

| 125 | 16...400 | 188 | 126 | 30 |

Other dimensions for flushing rings on request.