Factory Promotional Molybdenum Round Bar - Glass melting electrode – WINNERS

Factory Promotional Molybdenum Round Bar - Glass melting electrode – WINNERS Detail:

Product Description

Molybdenum electrode

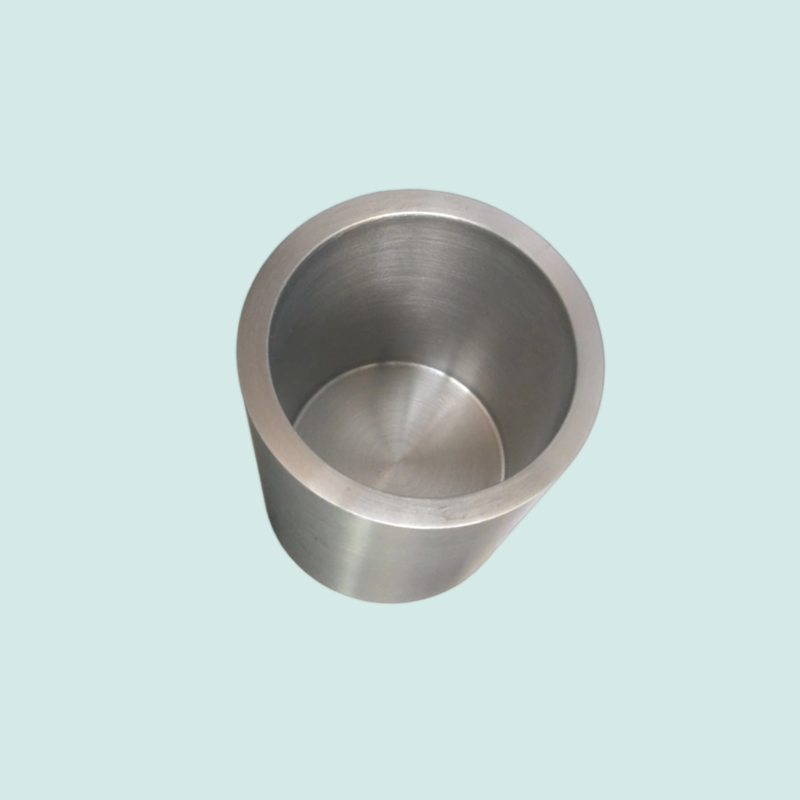

Molybdenum electrode is processed with molybdenum as raw material. The content of molybdenum in molybdenum electrode is 99.95%, and the density is greater than 10.15g / cm³. The use of molybdenum electrode instead of the original heavy oil and gas energy can effectively reduce environmental pollution and improve glass quality. The molybdenum electrode produced by us has high purity, long service life and a moderate price.

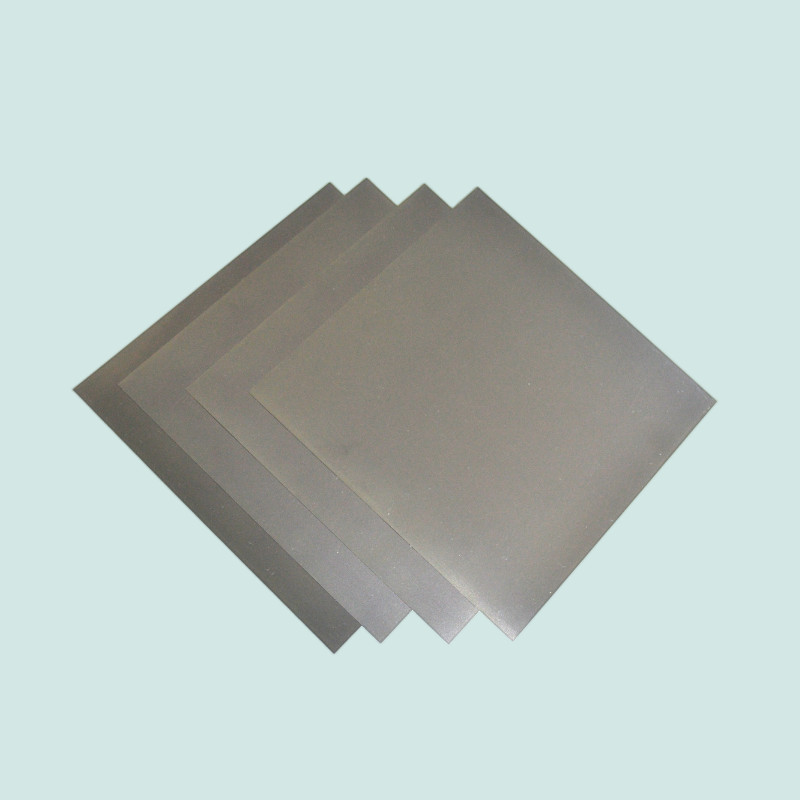

Molybdenum electrode can be divided into the electrode rod, electrode plate, electrode rod and screw electrode according to different shapes, and its use is slightly different. It is mainly used for heating equipment of glass fiber furnace and liquid orifice plate.

Product Parameters

|

Products name |

Molybdenum Electrode |

|

Diameter |

20~152.4mm |

|

Length |

Less than 1500mm |

|

Standard |

ASTM B387 |

|

Purity |

≥99.95% |

|

Surface |

Black,Polishing, Grinding bright |

|

Density |

10.15g/cm3 |

|

Technology |

Sintering,Forged |

|

MOQ |

1 piece |

NOTE: We can also provide MoLa electrodes and TZM electrodes.

*According to different processing methods, the surface is generally divided into: alkali-washed surface (silver-white metallic luster), forged surface (black surface), polished surface (metallic shiny surface).

Advantages of Using Molybdenum Electrodes

■ Low coefficient of thermal expansion.

■ High thermal and electrical conductivity.

■ Reduces detrimental glass discoloring.

■ Superior corrosion resistance.

■ Good machined ability.

■ Outstanding strength and stability at elevated temperatures up to 2000 °C.

With the wide application of molybdenum metal,

molybdenum electrodes have been used in these industries now:

■ Glass wool and thermal insulation cotton.

■ Optical glass, daily glass.

■ Rare earth industry, glass fiber.

■ Refractory fiber.

■ Glass liquid and water cooling jacket.

What can we do

If you’re not sure how to choose a molybdenum electrode, we can help you choose. Of course, we will make the most reasonable plan according to your actual needs and your budget.

Order Information

Inquiries and orders should include the following information:

☑ Surface of the Molybdenum Electrode (Black, Polishing or Grinding).

☑ Diameter, Length, Thread size or offering to us.

☑ Quantity (Even one piece we can provide).

Product detail pictures:

Related Product Guide:

We normally think and practice corresponding towards the change of circumstance, and grow up. We aim at the achievement of a richer mind and body plus the living for Factory Promotional Molybdenum Round Bar - Glass melting electrode – WINNERS , The product will supply to all over the world, such as: Ethiopia, Southampton, Israel, With excellent solutions, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We'll satisfy you with our qualified service!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.