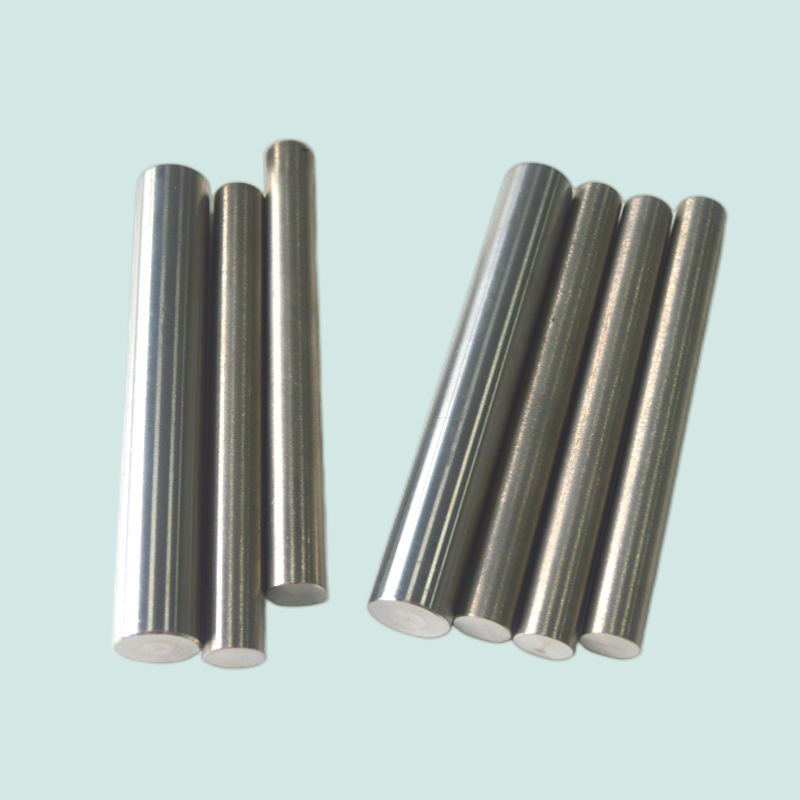

factory customized High Temperature Molybdenum Fittings - China Molybdenum Round Bar For Sale – WINNERS

factory customized High Temperature Molybdenum Fittings - China Molybdenum Round Bar For Sale – WINNERS Detail:

Product Description

Molybdenum rod has high melting point, good thermal conductivity and low thermal expansion properties. At high temperature, it can resist oxidation and has high strength. The properties of molybdenum and tungsten are very similar, their boiling point and electrical conductivity are outstanding, and the linear thermal expansion coefficient is small, which is easier to process than tungsten. Molybdenum rods can be used to manufacture electric vacuum devices and electric light source parts, as well as high temperature heating elements, high temperature structural parts, electrodes, etc.

Product Parameters

|

Products name |

Molybdenum rod bars for high temperature vacuum furnace |

|

Standard |

GBT 17792-2014 ASTM F289-96(2019) |

|

Available material |

Mo1(Pure Mo 99.95%), MoLa rod, TZM rod,MHC |

|

MOQ |

1Kg |

|

Technology process |

Forming, sintering, overhang forging, machining |

|

Surface |

black , alkali washing, polishing or grinding |

|

Feature |

high melting point, good thermal conductivity low thermal expansion properties |

Application

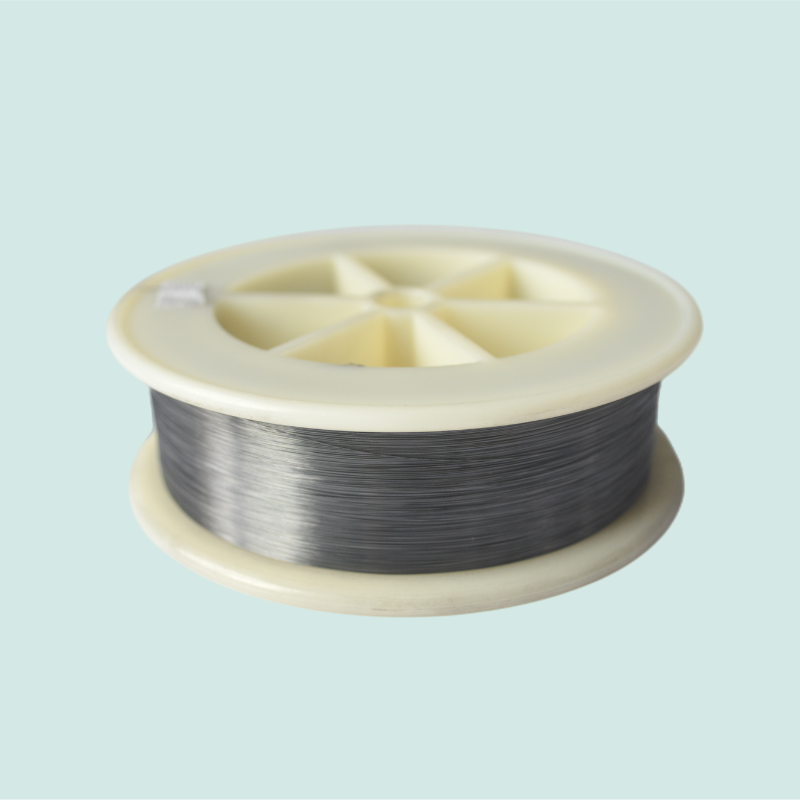

● Semiconductor ion implantation components.

● Electric light source and electric vacuum parts.

● Industrial high temperature furnace refractory parts.

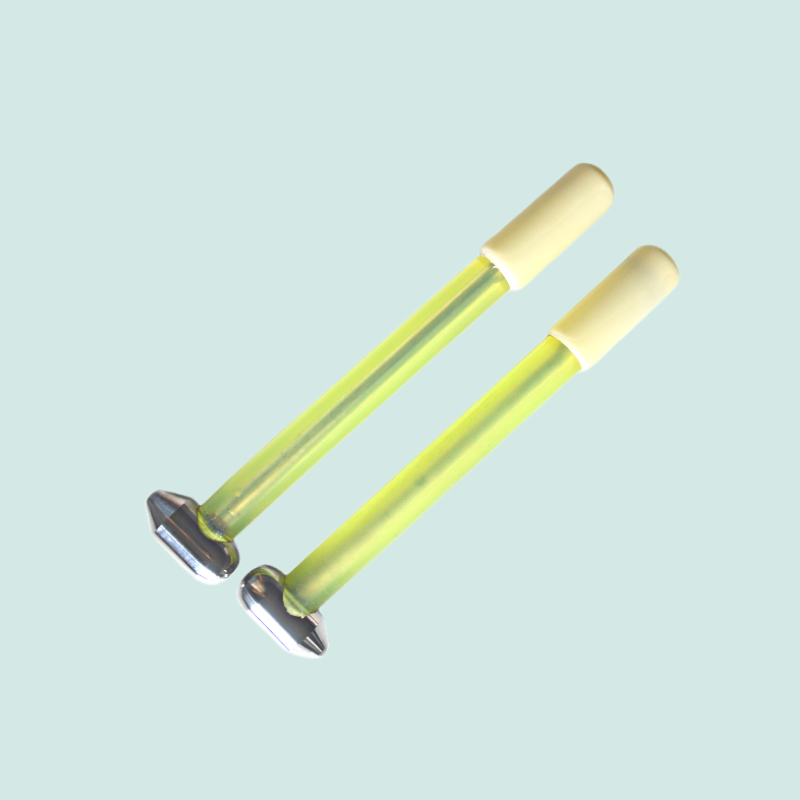

● Glass furnace molybdenum electrode.

● Used as electrode in rare earth industry.

Product Specifications

|

Surface |

Diameter |

Diameter tolerance |

Length |

Length tolerance |

Roughness |

|

Forged |

Φ2~Φ250 |

±1~±2 |

10~3000 |

±1~±2 |

Ra≤3.2 |

|

Lathed |

Φ2~Φ200 |

±0.01~±0.05 |

10~3000 |

±0.01~±1 |

Ra≤1.6 |

|

Grinding |

Φ2~Φ80 |

±0.01~±0.05 |

10~3000 |

±0.01~±1 |

Ra≤0.8 |

Note: Various specifications can be customized on demand.

Order Information

Inquiries and orders should include the following information.

● Diameter and length of Moly rods.

● Product surface: black, alkali washing, polishing or grinding, etc.

● Quantity or weight.

Product detail pictures:

Related Product Guide:

We usually keep on with the principle "Quality To start with, Prestige Supreme". We've been fully committed to offering our purchasers with competitively priced excellent solutions, prompt delivery and skilled support for factory customized High Temperature Molybdenum Fittings - China Molybdenum Round Bar For Sale – WINNERS , The product will supply to all over the world, such as: Nigeria, Brasilia, Puerto Rico, Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!