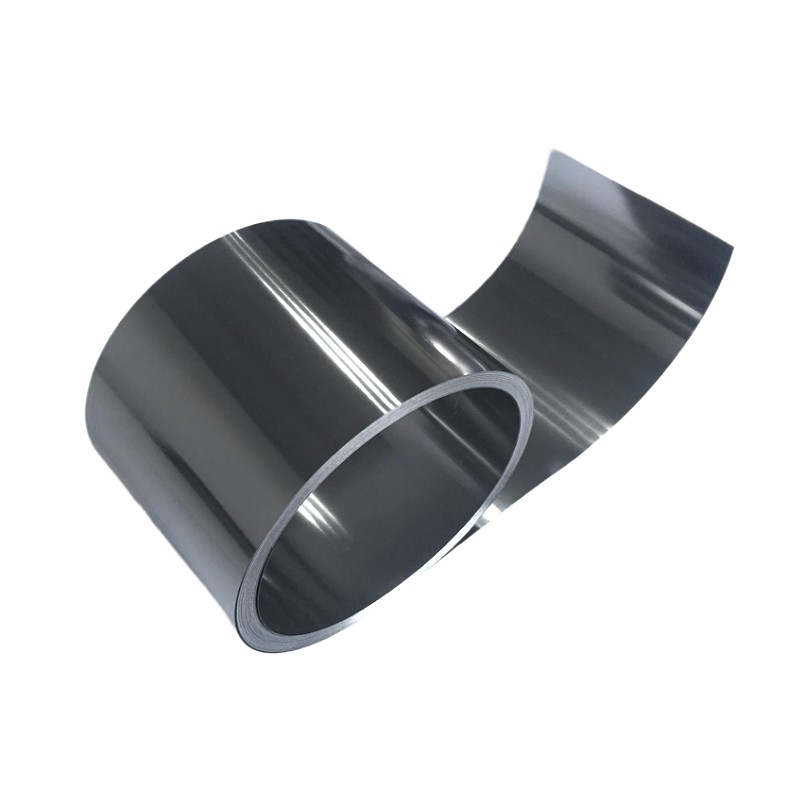

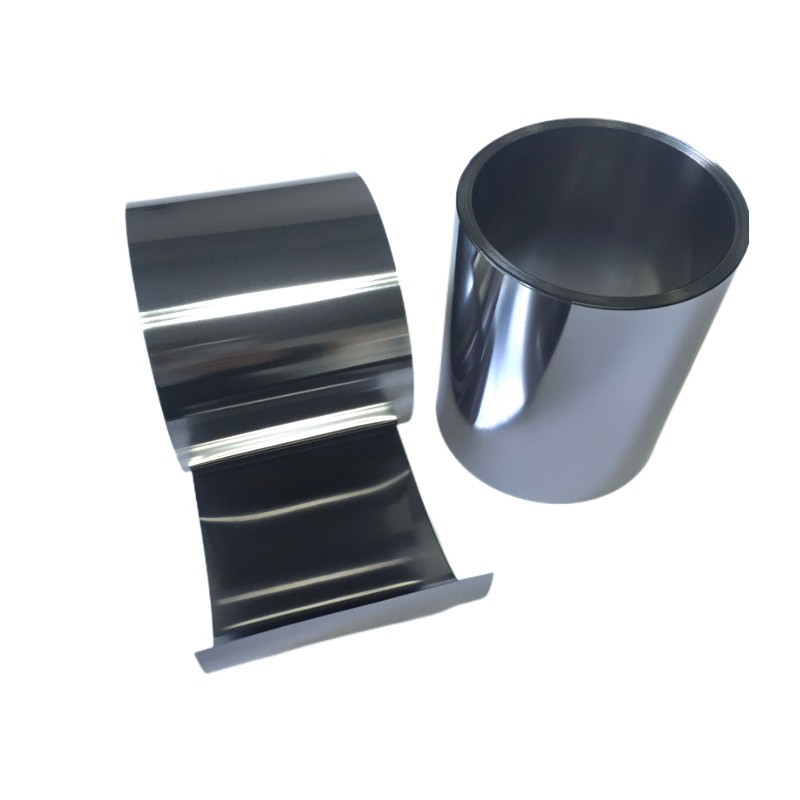

99.95% High Quality Tantalum Foil & Strip

Product Description

Tantalum foil has excellent corrosion resistance, high temperature stability, biocompatibility, good processability, and other characteristics, and is widely used in cutting-edge technology fields such as electronics, chemicals, medical treatment, and aerospace.

Tantalum foil can generally be produced and processed through powder metallurgy and rolling processes. We use advanced forging technology to refine the internal grains of tantalum ingots, and the,n through repeated precision rolling and annealing, the foil reaches the finished thickness. The finished tantalum foil has high purity (Ta≧99.95%), precise size, bright surface, no cracks, no peeling, good flatness, and meets ASTM B708 standards.

We also offer tantalum rods, tubes, sheets, wire, and tantalum custom parts. If you have product needs, please email us at info@winnersmetals.com or call us at +86 156 1977 8518 (WhatsApp).

Applications

• Electronics and Semiconductors

• Chemical processing

• Medical instruments

• Aerospace and defense

• Vacuum furnace

• Thin film deposition

Specifications

| Production Name | Tantalum foil |

| Standard | ASTM B708 |

| Material | R05200, R05400, R05252(Ta-2.5W), R05255(Ta-10W) |

| Specification | Thickness (0.025mm-10mm), length, and width can be customized. |

| Supply Status | Annealed |

|

Forms |

Thickness (mm) |

Width (mm) |

Length (mm) |

|

Tantalum Foil |

0.025-0.09 |

30-150 |

<2000 |

|

Tantalum Sheet |

0.1-0.5 |

30-600 |

30-2000 |

|

Tantalum Plate |

0.5-10 |

50-1000 |

50-2000 |

|

*Other sizes available on request. |

|||

Element Content & Mechanical Properties

Element Content

|

Element |

R05200 |

R05400 |

RO5252(Ta-2.5W) |

RO5255(Ta-10W) |

|

Fe |

0.03%max |

0.005%max |

0.05%max |

0.005%max |

|

Si |

0.02%max |

0.005%max |

0.05%max |

0.005%max |

|

Ni |

0.005%max |

0.002%max |

0.002%max |

0.002%max |

|

W |

0.04%max |

0.01%max |

3%max |

11%max |

|

Mo |

0.03%max |

0.01%max |

0.01%max |

0.01%max |

|

Ti |

0.005%max |

0.002%max |

0.002%max |

0.002%max |

|

Nb |

0.1%max |

0.03%max |

0.04%max |

0.04%max |

|

O |

0.02%max |

0.015%max |

0.015%max |

0.015%max |

|

C |

0.01%max |

0.01%max |

0.01%max |

0.01%max |

|

H |

0.0015%max |

0.0015%max |

0.0015%max |

0.0015%max |

|

N |

0.01%max |

0.01%max |

0.01%max |

0.01%max |

|

Ta |

Remainder |

Remainder |

Remainder |

Remainder |

Mechanical Properties (Annealed)

|

Grades and Forms |

Tensile Strength Min, psi (MPa) |

Yield Strength Min, psi (MPa) |

Minimum Elongation, % |

|

|

RO5200, RO5400 (plate, sheet, and foil) |

Thickness<0.060"(1.524mm) |

30000 (207) |

20000 (138) |

20 |

|

Thickness≥0.060"(1.524mm) |

25000 (172) |

15000 (103) |

30 |

|

|

Ta-10W (RO5255) |

Thickness<0.125" (3.175mm) |

70000 (482) |

60000 (414) |

15 |

|

Thickness≥0.125" (3.175mm) |

70000 (482) |

55000 (379) |

20 |

|

|

Ta-2.5W (RO5252) |

Thickness<0.125" (3.175mm) |

40000 (276) |

30000 (207) |

20 |

|

Thickness≥0.125" (3.175mm) |

40000 (276) |

22000 (152) |

25 |

|

|

Ta-40Nb (R05240) |

Thickness<0.060"(1.524mm) |

35000 (241) |

20000 (138) |

25 |

|

Thickness≥0.060"(1.524mm) |

35000 (241) |

15000 (103) |

25 |

|