Best quality Moly Rod For Glass Melting - Factory price Tungsten based heavy alloy – WINNERS

Best quality Moly Rod For Glass Melting - Factory price Tungsten based heavy alloy – WINNERS Detail:

Product Parameters

Application of molybdenum alloy

Tungsten-nickel-iron alloy is widely used and has become the main tungsten-based heavy alloy with the largest amount. For general applications, such as counterweights, counterweights, radiation shielding devices, etc., sintered alloys are directly used; but for applications requiring high mechanical properties, tungsten-nickel-iron alloys require deformation processing and heat treatment to achieve strengthening.

■ Tungsten-nickel-iron alloys are mainly used in the manufacture of gyroscope rotors, guide devices and shock absorbers for aviation and spacecraft;

■ Die-casting molds, tool holders, boring bars and automatic watch weights for machinery manufacturing;

■ Armor-piercing bullet cores for conventional weapons, rivet heads and switch contacts for electrical products;

■ In addition, it also uses to manufacture various radiation shielding parts, etc.

Conventional tungsten nickel iron alloy properties

|

Grade |

chemical composition% |

Density (g/cm3) |

Tensile strength (MPa) |

Yield Strength (MPa) |

Elastic Modulus (%) |

HardnessMax (HRC) |

magnetic |

|

|

W |

NiFe |

|||||||

|

ATM1700 |

90 |

Bal |

16.85~17.25 |

≥758 |

≥517 |

≥5 |

32 |

yes |

|

ATM1750 |

92.5 |

Bal |

17.15~17.85 |

≥758 |

≥517 |

≥5 |

33 |

yes |

|

ATM1800 |

95 |

Bal |

17.75~18.35 |

≥724 |

≥517 |

≥3 |

34 |

yes |

|

ATM1850 |

97 |

Bal |

18.25~18.85 |

≥689 |

≥517 |

≥2 |

35 |

yes |

Why choose us

The powder metallurgy process is used to complete the production of tungsten-nickel-iron alloys in strict accordance with ISO 9001 quality standards. The products fully meet the specifications and requirements of AMS-T-21014 and ASTM-B-777-99 (MIL-T-21014).

Order Information

Inquiries and orders should include the following information:

☑Composition ratio of tungsten, nickel and Iron ☑Diameter and Length ☑Quantity

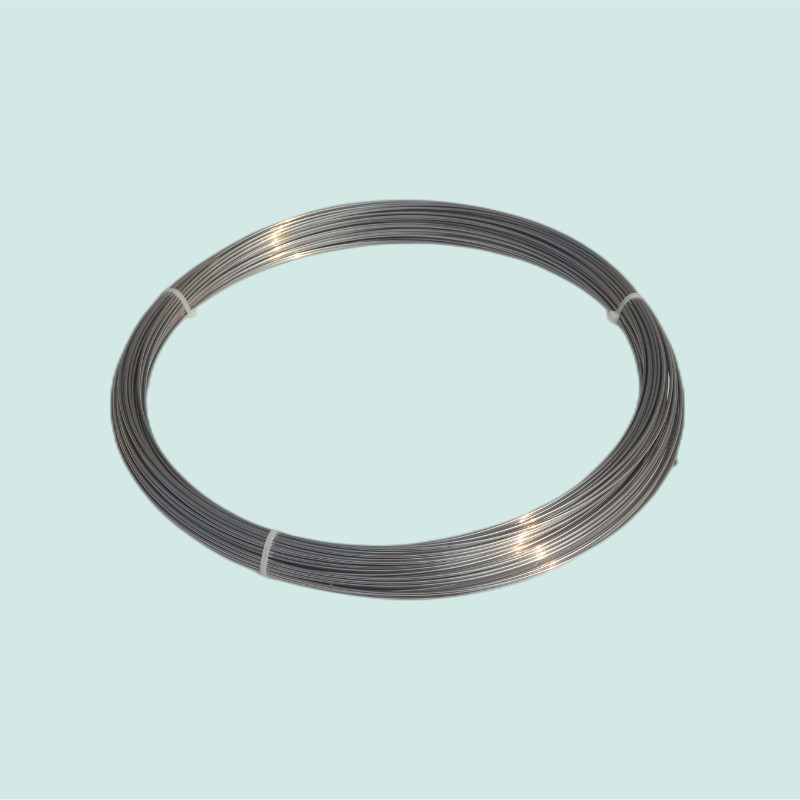

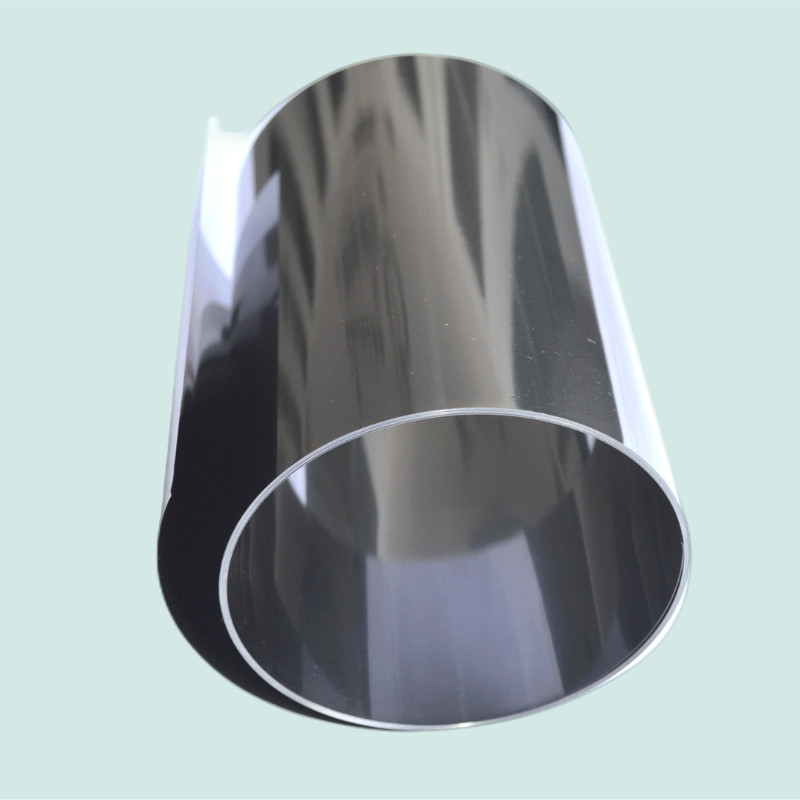

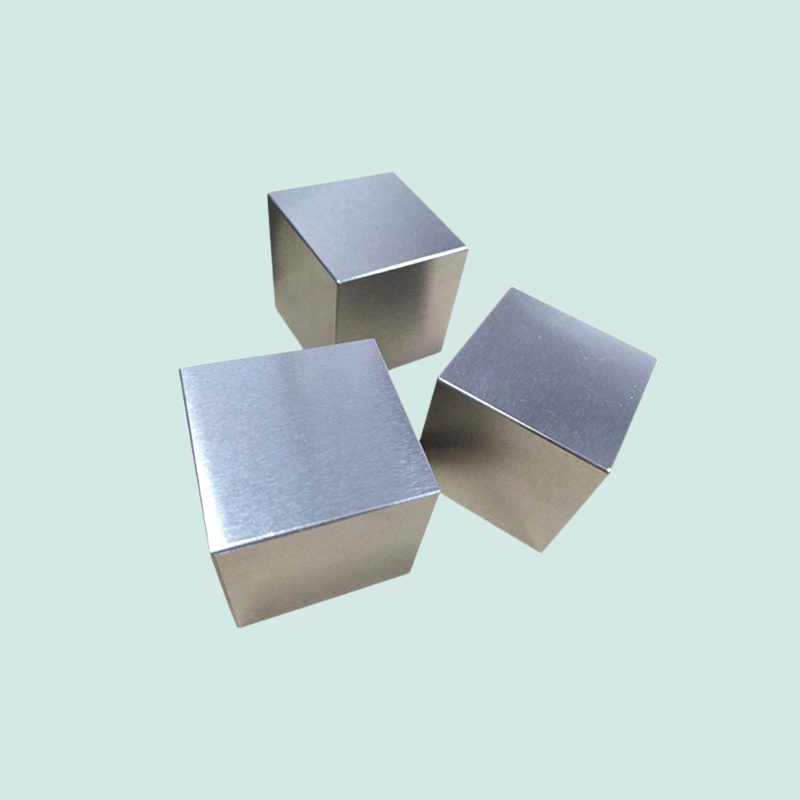

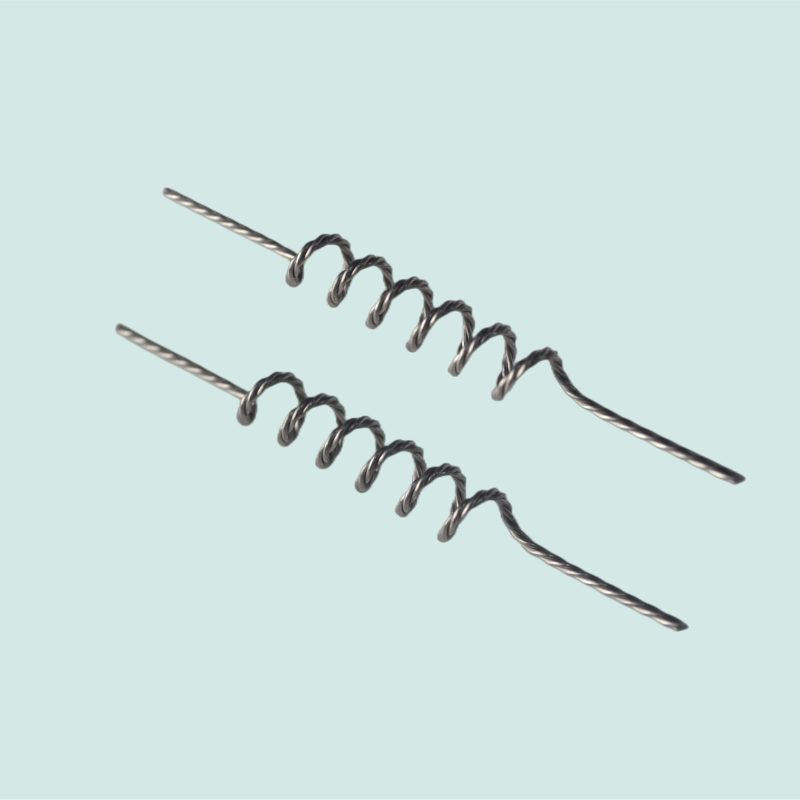

Product detail pictures:

Related Product Guide:

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for Best quality Moly Rod For Glass Melting - Factory price Tungsten based heavy alloy – WINNERS , The product will supply to all over the world, such as: Turkmenistan, Bangkok, Lyon, Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, please feel free to contact us for quotation and product details.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,