2022 Latest Design Metal Diaphragm - Sputtering target Titanium 99.7 – WINNERS

2022 Latest Design Metal Diaphragm - Sputtering target Titanium 99.7 – WINNERS Detail:

Product Description

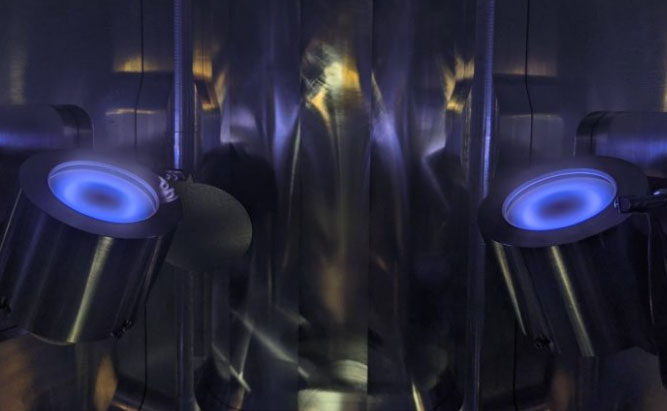

How Does Magnetron Sputtering Work?

Magnetron sputtering is a physical vapour deposition (PVD) method, a class of vacuum deposition processes for producing thin films and coatings.

The name “magnetron sputtering” arises from the use of magnetic fields to control the charged ion particles’ behaviour in the magnetron sputter deposition process. The process requires a high vacuum chamber to create a low-pressure environment for sputtering. The gas that comprises the plasma, typically argon gas, enters the chamber first.

A high negative voltage is applied between the cathode and the anode to initiate the ionisation of the inert gas. Positive argon ions from the plasma collide with the negatively charged target material. Each collision of high energy particles can cause atoms from the target surface to eject into the vacuum environment and propel onto the surface of the substrate.

A strong magnetic field produces high plasma density by confining the electrons near the target surface, increasing the rate of deposition and preventing damage to the substrate from ion bombardment. Most materials can act as a target for the sputtering process since the magnetron sputtering system does not require melting or evaporation of the source material.

Product Parameters

| Products name | Pure titanium target |

| Grade | Gr1 |

| Purity | More 99.7% |

| Density | 4.5g/cm3 |

| MOQ | 5 pieces |

| Hot sale size | Φ95*40mm Φ98*45mm Φ100*40mm Φ128*45mm |

| Application | Coating for PVD machine |

| Stock size | Φ98*45mm Φ100*40mm |

| Other available Targets | Molybdenum(Mo) Chrome(Cr) TiAl Copper(Cu) Zirconium(Zr) |

Application

● Coating integrated circuits.

● Surface panel displays of flat panels and other components.

● Decoration and glass coating, etc.

Order Information

Inquiries and orders should include the following information

● Diameter, Height(such like Φ100*40mm).

● Thread size (Such like M90*2mm).

● Quantity.

● Purity demand.

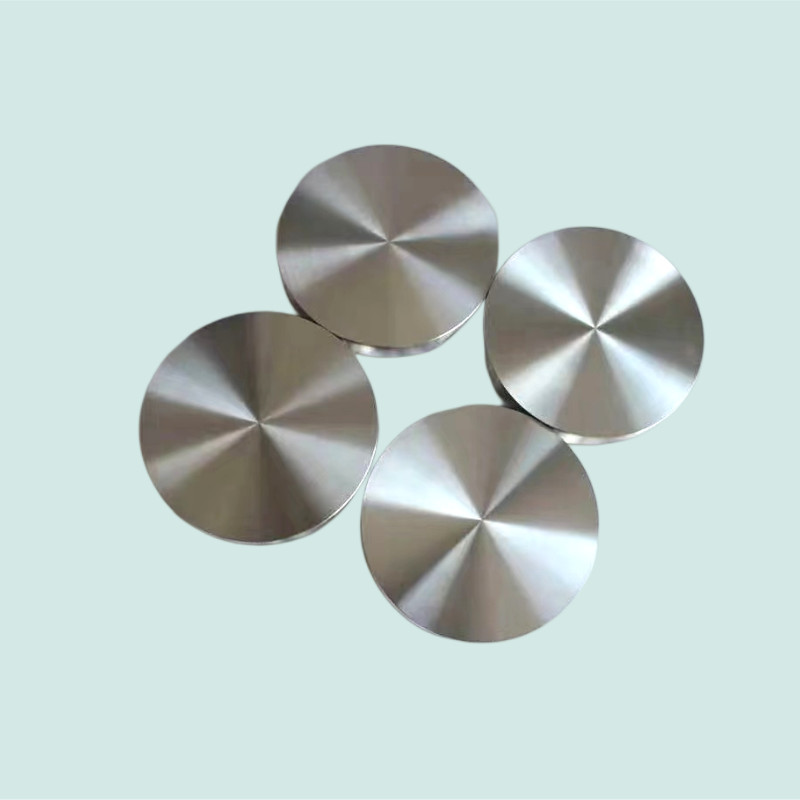

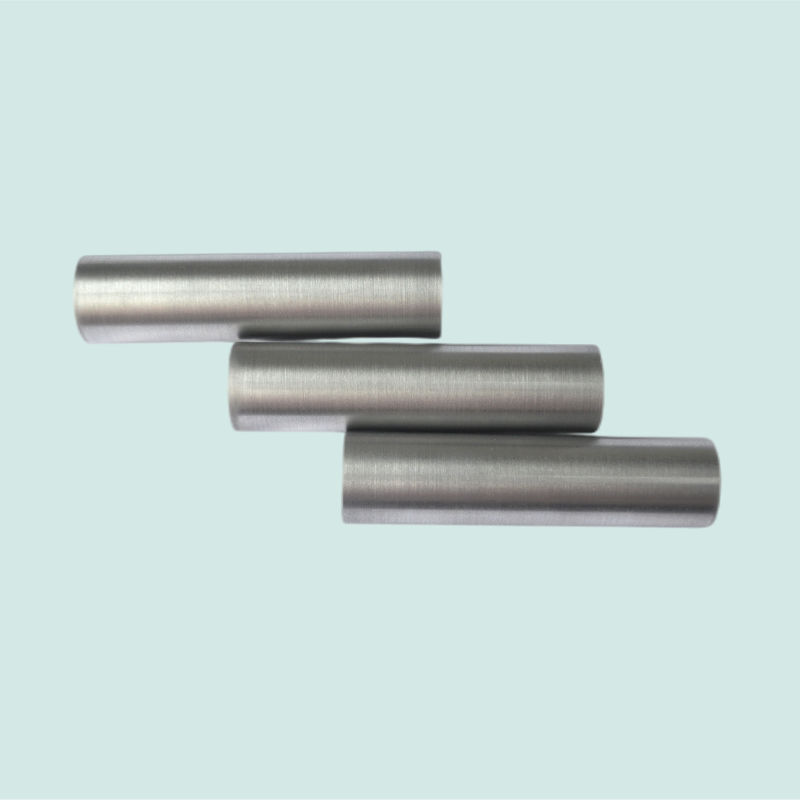

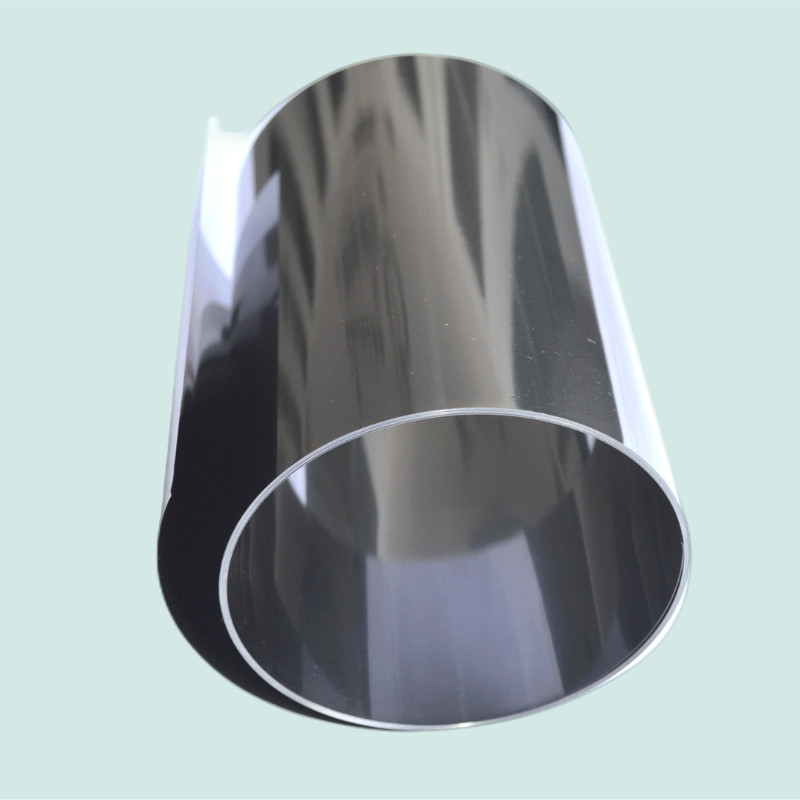

Product detail pictures:

Related Product Guide:

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for 2022 Latest Design Metal Diaphragm - Sputtering target Titanium 99.7 – WINNERS , The product will supply to all over the world, such as: Philippines, Naples, Pakistan, Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will be highly appreciated.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.